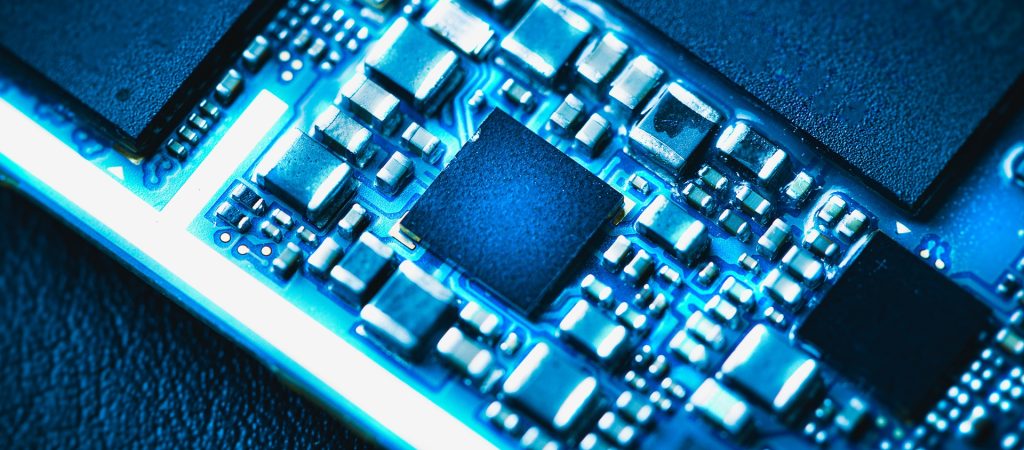

Putting factory-based production in the spotlight

Are manufacturers prioritising investment in digital capability and Industry 4.0 technologies?

Vendigital has vast experience of working in partnership with industrial manufacturing clients to create more agile operations and transform their cost bases. By focusing on productivity, operational cost and performance we can help you to implement stepped changes that really make a difference.

Our industrial manufacturing consultants have extensive experience, ensuring we have a deep understanding of your challenges and how to achieve your cost transformation goals. Whether it’s the increased use of automation and emerging technology mixed with using data from legacy systems, the need to build agile, resilient and future-proofed supply chains or the pressure to reduce carbon footprint without radically increasing costs, we understand the challenges faced and know what it takes to deliver long-lasting results.

By combining industrial manufacturing consulting expertise and our proprietary digital platform, we deploy data-driven insights to deliver quantifiable operational cost savings and embed cost analytics capability to enable clients to achieve efficiencies on an ongoing basis.

Whether you’re looking to make longer-term strategic cost decisions or drive operational efficiencies at pace, we work as part of your team to achieve measurable and sustainable cost benefits.

The industrial manufacturing landscape is constantly evolving, and technological advances must be effectively incorporated into existing legacy systems in order to drive operational cost efficiencies and ensure sustained competitiveness.

Our team of industrial manufacturing consultants are focused on tackling the unique challenges faced by the sector and finding effective solutions to ensure that our clients can benefit from quantifiable cost benefits – both short and long term.

• Managing increasing automation and integration of the Internet of Things into existing legacy systems

• Reducing the cost and risk of R&D

• Improving production through the use of new technology and innovation

• Cutting costs while increasing resilience to deal with future disruption

• Implementing rapid waste reduction to improve process efficiencies and reduce costs

• Identifying leaks in margins to increase profitability

• Predicting, managing and responding to fluctuations in customer demand

• Reducing the operational carbon footprint

• Creating a strategic vision that maximises opportunities for manufacturing

Looking for an industry expert?

We help firms drive cost efficiencies across their complex operations. Our team of industrial manufacturing consultants, drawn from the sector directly, understand the industry and are focused on tackling its unique challenges, finding effective solutions to overcome them.

We combine multi-disciplinary consulting expertise with our proprietary digital platform to deploy data-driven operational insights to embed measurable and sustainable cost benefits across your business.

We do this across:

We’re focused on driving cost transformation through identifying and addressing the key strategic, performance, operational and cost levers across your manufacturing operations. These can include building agility into the supply chain to minimise disruption and increase margins; strategic sourcing activities to find the right suppliers, in the right geographies at the right cost; or optimising manufacturing processes to achieve efficiency across your complex end-to-end operations and reduce internal costs. In addition, we can we benchmark costs to determine ‘should cost’ and assess the value in making vs buying parts to optimise production and drive out cost. Using financial modelling across your product mix we are able to determine how each product in your portfolio is performing, giving you the visibility to inform strategic decisions around which products to grow and invest in.

We don’t just advise you on what needs to be done, we work with you to execute the plan achieving quick win cost savings and long-lasting strategic cost efficiencies.

Get in touch to find out how our industrial manufacturing consultants can partner with you to achieve your cost transformation requirements.

We are ideally placed to help complex businesses accelerate the transformation of their cost bases.

Client collaboration is at the heart of our approach

We cut through complexity quickly

We're focused on delivering long-term outcomes for clients

We work with clients to set the strategy and deliver the nuts and bolts of the solution

Intelligent approach to cost optimisation through deep understanding of cost and cost drivers

Deliver quantifiable cost reductions through our cost neutral fee structure

Are manufacturers prioritising investment in digital capability and Industry 4.0 technologies?

With the government’s renewed focus on upgrading national infrastructure, clean energy providers must ensure their supply chains and processes are fully optimised ahead of any increased demand.

When it comes to new product innovation (NPI), there’s no such thing as a one-size-fits-all approach and engineers often find that juggling different priorities leads to costly, late-stage design changes.