The Future of Packaging: Balancing Sustainability, Cost, and Innovation

We will explore how businesses can more effectively navigate an evolving market landscape by critically evaluating their existing packaging strategies and exploring innovative alternatives.

Is your thriving food and drink business ready to scale?

We discuss how should food and drink businesses prepare to scale and when should they move from planning to implementation.

Optimising perishable inventory

In this insight we outline five ways to improve inventory management for products with a short shelf life.

How cost-carbon efficient is your NPD process?

New product development (NPD) in the FMCG sector often comes with high cost and carbon implications. Businesses must create a holistic process that considers these aspects from ideation through to waste minimisation.

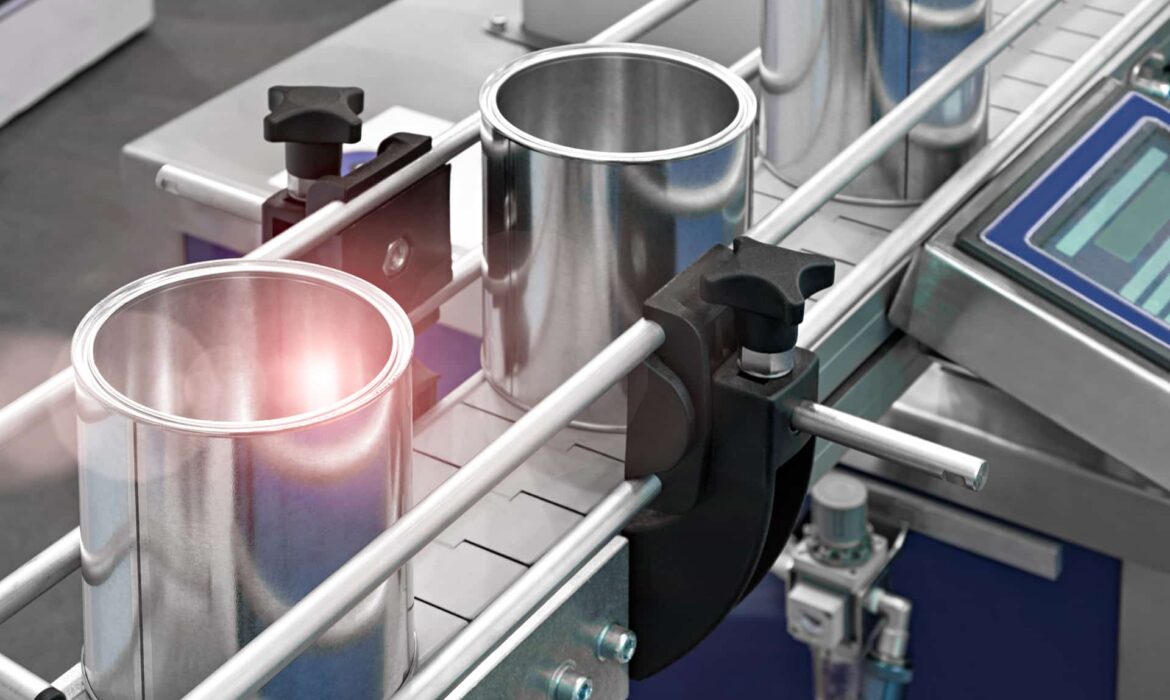

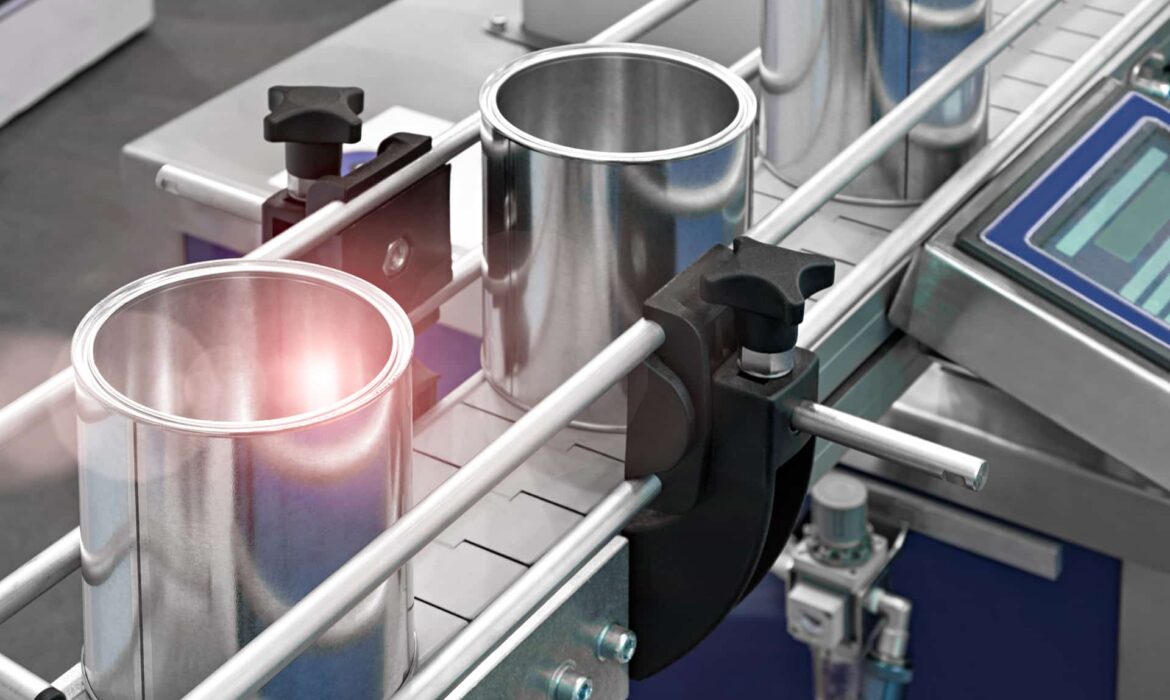

FMCG manufacturing – data visibility is key to cost and carbon efficiency

An accurate and holistic understanding of the carbon and cost impact of each facet of business operations is imperative to stay competitive.

Walking the tightrope

In a difficult economic climate for both consumers and business, food and drink producers face a delicate balancing act to keep costs down while maintaining quality for customers.

Cost and Carbon Reduction through Operational Excellence

Adopting operational excellence can help to achieve both short- and long-term goals across cost and carbon, creating competitive advantage and enabling more effective investment decisions.

What’s driving your product and pricing decisions?

Product and pricing decisions are key to survival. But how can a complex business make these decisions amidst so much uncertainty? The answer lies in data understanding.

Creating a competitive advantage in carbon and production cost

Through scenario modeling, the true impact on carbon emissions and product cost can be identified. This can be a competitive advantage to make informed decisions and identify levers that reduce carbon and cost.