Putting factory-based production in the spotlight

Are manufacturers prioritising investment in digital capability and Industry 4.0 technologies?

Should Cost modelling is a crucial practice in many industries, aimed at understanding and optimising the costs associated with manufacturing a product or delivering a service.

At its core, Should Cost modelling involves breaking down the components, processes, and resources involved in manufacturing or delivering a product or service, and then estimating what the cost should be under optimal conditions. This enables the business to leverage this data and gain competitive advantage in supplier negotiations. It is a great method for enabling engineering and procurement to work together, to deliver value.

The key to successful Should Cost modelling is the availability and accuracy of good data. The scarcity or inaccuracy of internal engineering, manufacturing and supply chain data coupled with external benchmark information often prevents teams from being able to execute this methodology effectively.

Process

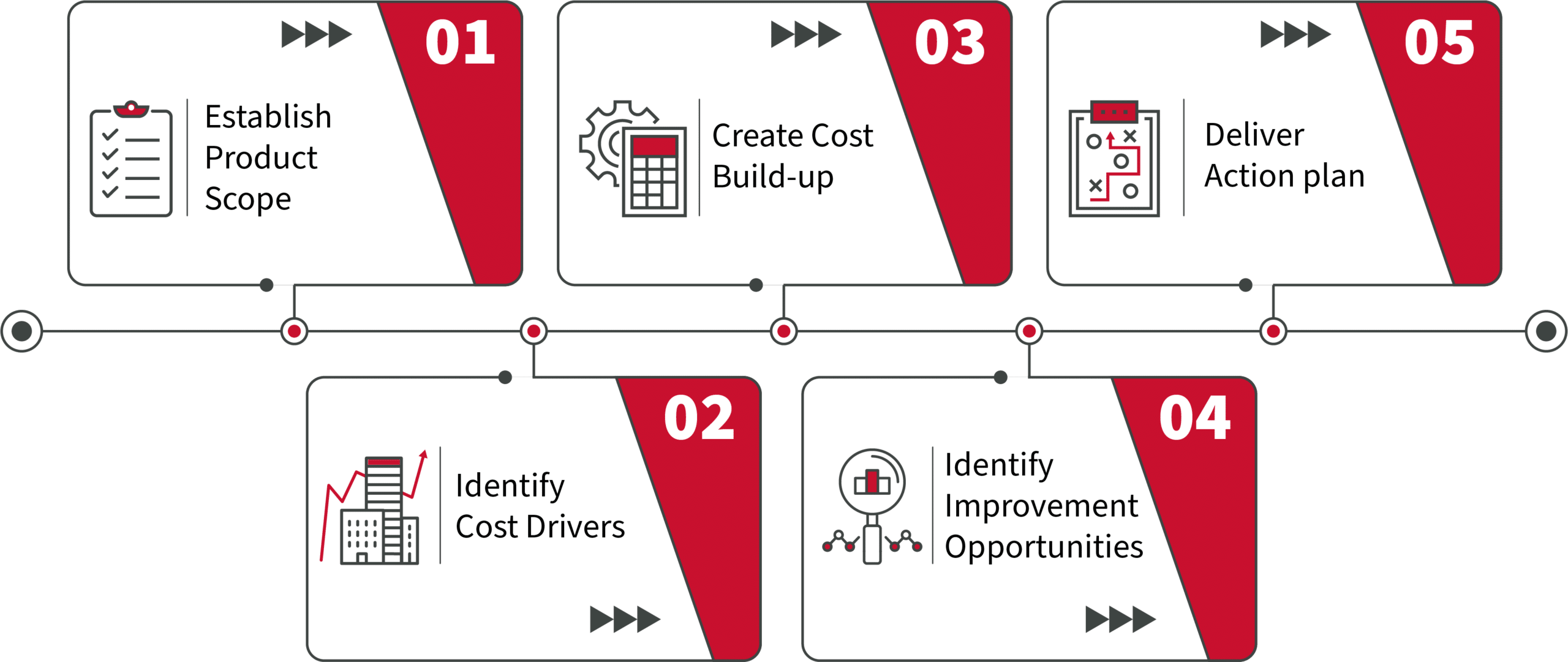

Effective Should Cost modelling follows a 5-step process:

5-step Should Cost modelling process

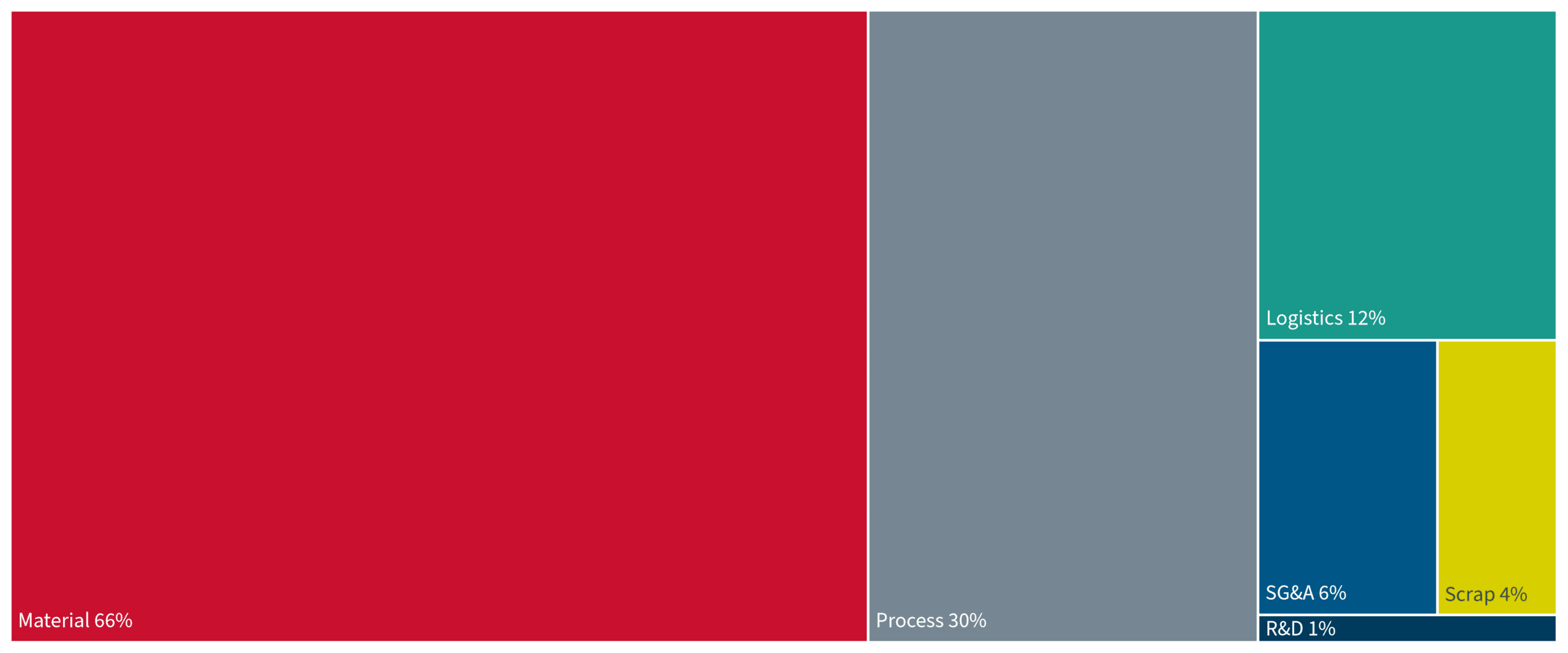

Cost drivers

One of the primary techniques used in Should Cost modelling is a detailed analysis of the various cost drivers involved in production or service delivery. This analysis typically includes factors such as raw material costs, labour costs, overhead expenses, transportation costs, and any other relevant expenses. By thoroughly understanding these cost drivers, companies can develop a comprehensive model of what the cost of producing or delivering a product or service should be. Often companies do not have full transparency of their cost base or access to accurate data to build a successful cost model but putting effort into measuring some key costs is critical to an accurate model.

Example of Should Cost drivers and cost build-up

Benchmarking

Another key aspect of Should Cost modelling is benchmarking. This involves comparing the estimated costs derived from the modelling process with external benchmarks, such as industry standards or the costs of similar products or services offered by competitors. Benchmarking provides valuable insights into areas where costs may be higher than they should be, allowing companies to identify opportunities for cost reduction and process improvement. Leveraging 15+ years of benchmark data for material and manufacturing costs across any geography proves highly valuable to our clients and allows targets to be applied to each of the cost drivers.

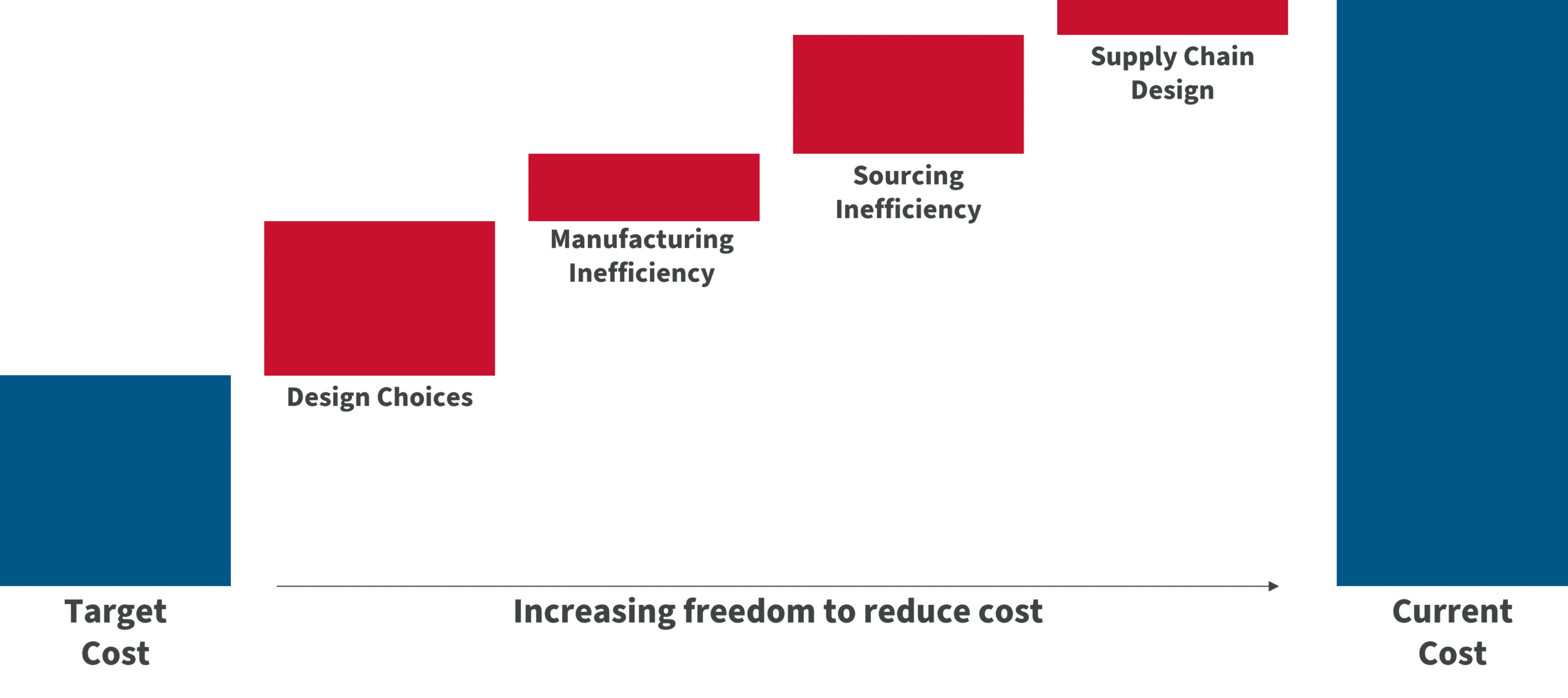

Opportunities

Once the opportunities and targets have been identified, where the product sits in its lifecycle and its different cost elements will determine the ease of the improvement activity. Typically, they are grouped into 4 areas:

Each of these areas can offer valuable cost reduction opportunities from the modelling exercise with varying degrees of freedom to make changes. Reducing supply chain costs or improving a purchasing contract can typically be don quite freely with effective planning. Making cost reductions within manufacturing plants is also possible with lean tools and continuous improvement methods but by the time the focus turns to design changes and optimisation, the task becomes more challenging. Typically, 80% of product costs are baked in during the design and development of a product and make significant improvements can often be challenging and require engineering effort. For example, relaxing a material specification to introduce a lower cost or more readily available steel would probably require expensive and time-consuming modelling and validation testing.

Example of gap to target cost

Within each of these areas there will be specific actions and activities to enable the team to get closer to the target cost. One example of this is using the data as a powerful tool for supplier negotiations. Armed with a detailed understanding of the cost drivers involved in production, companies can negotiate more effectively with suppliers, driving down costs and improving their overall profitability. Often supplier relationships can be improved and fostered by having fact-based, data led discussions.

Benefit

The benefits of applying Should Cost modelling are manifold. Firstly, it provides companies with a clear understanding of the cost structure of their products or services, enabling more informed decision-making around pricing, sourcing, and resource allocation. By identifying areas of inefficiency or excess cost, Should Cost modelling can help companies optimise their operations and improve their competitiveness in the market.

Moreover, Should Cost modelling fosters collaboration between different departments within an organisation, such as engineering, procurement, and finance. By involving various stakeholders in the modelling process, companies can leverage their collective expertise to identify cost-saving opportunities and develop more accurate cost estimates.

In summary, Should Cost modelling is a valuable practice for companies looking to optimise their operations, reduce costs, and improve their competitiveness in the market. By analysing cost drivers, benchmarking against industry standards, and fostering collaboration across departments, companies can unlock significant value and drive sustainable growth.

Take control of your costs – book a 30 minute slot with one of our cost transformation experts

Curious how you could accelerate the journey to cost reduction in your business? Book a free, no-obligation 30-minute consultation with one of our cost transformation experts to discuss your current operational challenges, specific ambitions and explore tailored strategies to achieve your cost reduction goals.

To benefit from our team’s deep operational expertise, simply click the link below and we’ll come right back to you.

Sign up to get the latest insights from Vendigital

Related Insights

Are manufacturers prioritising investment in digital capability and Industry 4.0 technologies?

With the government’s renewed focus on upgrading national infrastructure, clean energy providers must ensure their supply chains and processes are fully optimised ahead of any increased demand.

When it comes to new product innovation (NPI), there’s no such thing as a one-size-fits-all approach and engineers often find that juggling different priorities leads to costly, late-stage design changes.

Subscribe to our newsletter

Take control of your costs – book a 30 minute slot with one of our cost transformation experts

Book a free, no-obligation 30-minute consultation with one of our cost transformation experts to discuss your current operational challenges, specific ambitions and explore tailored strategies to achieve your cost reduction goals.