Driving costs, productivity and pace in construction projects

Poor productivity and pace slippage in construction costs money and damages projects margins. We explore how productivity can be measured and improved.

The future is vertical

Paul Adams considers recent developments in the UK to accelerate the future of urban air mobility. How will these tech disruptors transform existing aerospace supply chains?

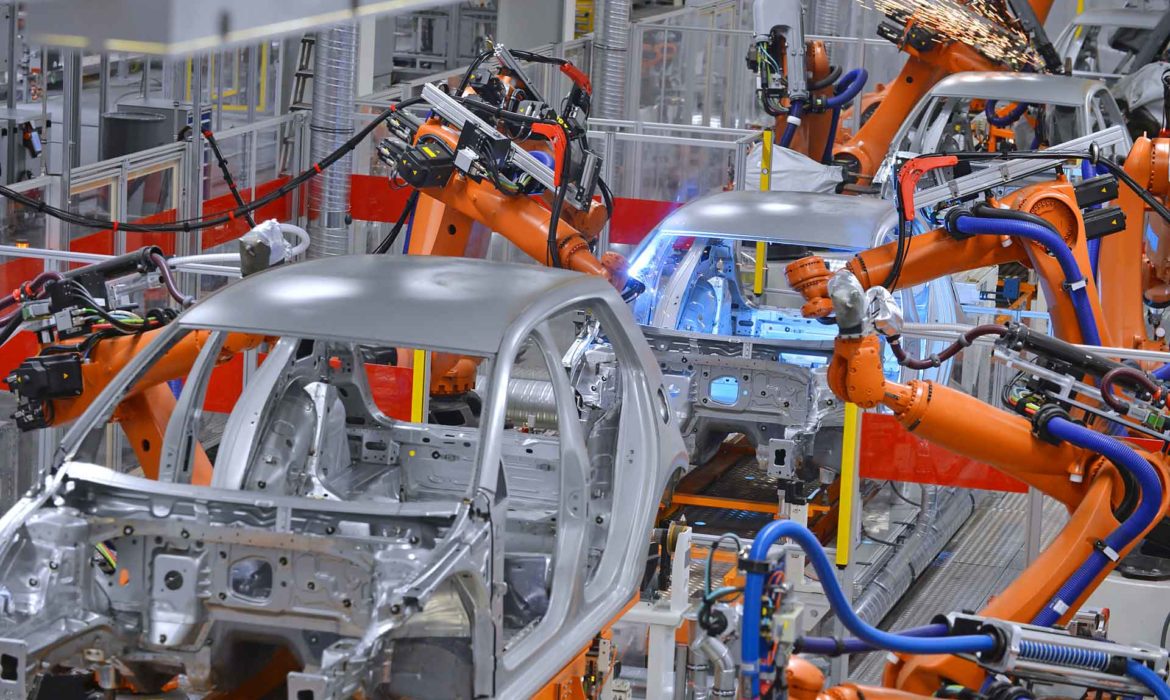

The changing world of Electric Vehicle supply chains

The whole automotive industry is engaged in a pivot towards Battery Electric Vehicles. Supply chain design is a crucial element in achieving the required pivot.

More EVs are coming, but will the price be right?

Justin Benson considers the importance of balancing brand and price as established car makers line up to launch new mass market EVs.

Removing and controlling costs – a strategic imperative for construction firms

Long-standing low and recently falling margins in construction are in danger of becoming an expected norm. But does it really have to be that way?

Future proofing the supply chain is critical to achieving competitive advantage

The challenges and benefits of building supply chain resilience and how businesses should look to future proof their supply chain as an enabler of competitive advantage.

Supply chain understanding and development is key to retrofit success

Action is needed to upgrade the energy efficiency homes and other buildings in the UK. However, issues must be addressed to implement the retrofit programme.

Building supply chain agility is now more critical than ever

The pandemic has provided a reminder of just how unpredictable patterns of supply and demand can be. Customers now expect a rapid, demand-driven approach to order fulfilment.

Robust, ongoing supply chain assessment is a critical underpin to strategic decision-making

Justin Benson discusses the importance of ongoing supply chain assessment, highlights some of the challenges involved and outlines how businesses can look to do this effectively.