Is the clean energy supply chain ready for grid expansion?

With the government’s renewed focus on upgrading national infrastructure, clean energy providers must ensure their supply chains and processes are fully optimised ahead of any increased demand.

How cost-carbon efficient is your NPD process?

New product development (NPD) in the FMCG sector often comes with high cost and carbon implications. Businesses must create a holistic process that considers these aspects from ideation through to waste minimisation.

Right size your inventory

By reviewing inventory management across the value chain, there could be an opportunity to right size stock and optimise much-needed working capital.

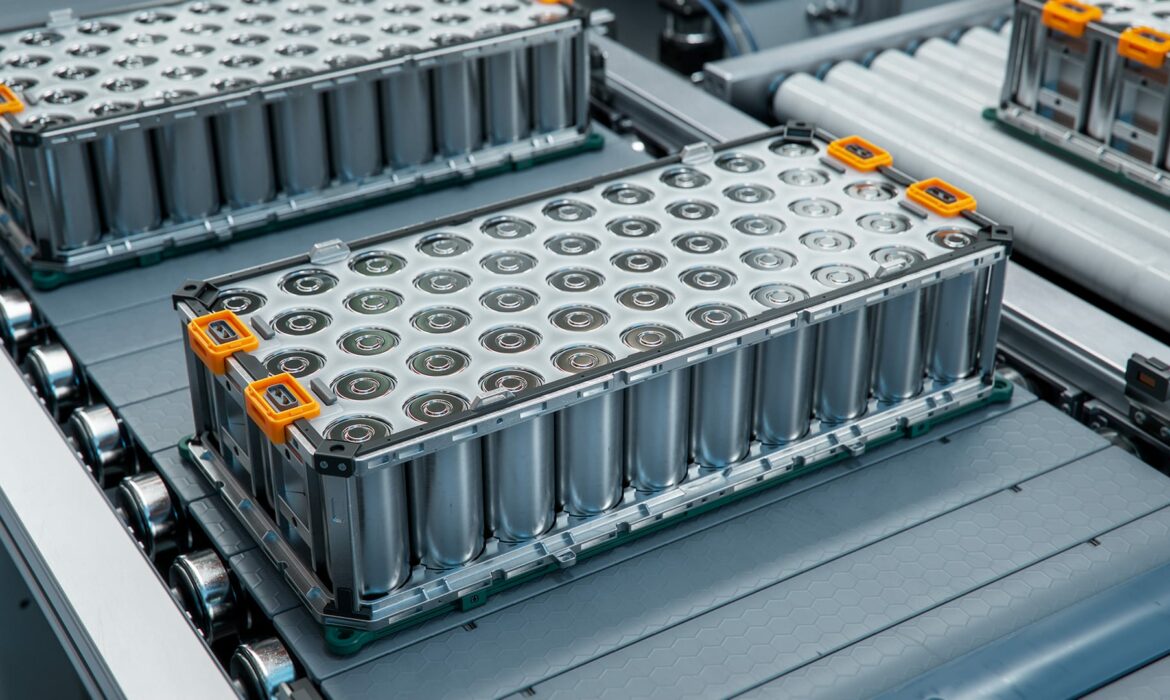

The challenge of used EV achieving price parity

Used EVs are now attracting residual values close to those of used ICE vehicles. However, barriers to sale remain, with many consumers still concerned about access to charging infrastructure and total running costs.

Using GenAI to achieve operational excellence

The boom in Generative AI is creating new opportunities for aerospace and defence sector manufacturers. Used correctly, GenAI capability can help to optimise production processes, improve supply chain resilience, ringfence knowledge and reduce costs.

Digital supply chain collaboration is a new deterrent

Ongoing instability has brought pressures for defence industry manufacturers, requiring greater focus on supply chain resilience. Working collaboratively helps to mitigate supply chain risks, while creating a stronger national deterrent.

Fracturing supply chains: where will it end?

It seems that examples of supply chain disruption are all around. What started out as a symptom of the post-Covid ramp-up is now part of the new order, but what is causing all this disruption and will it ever end?

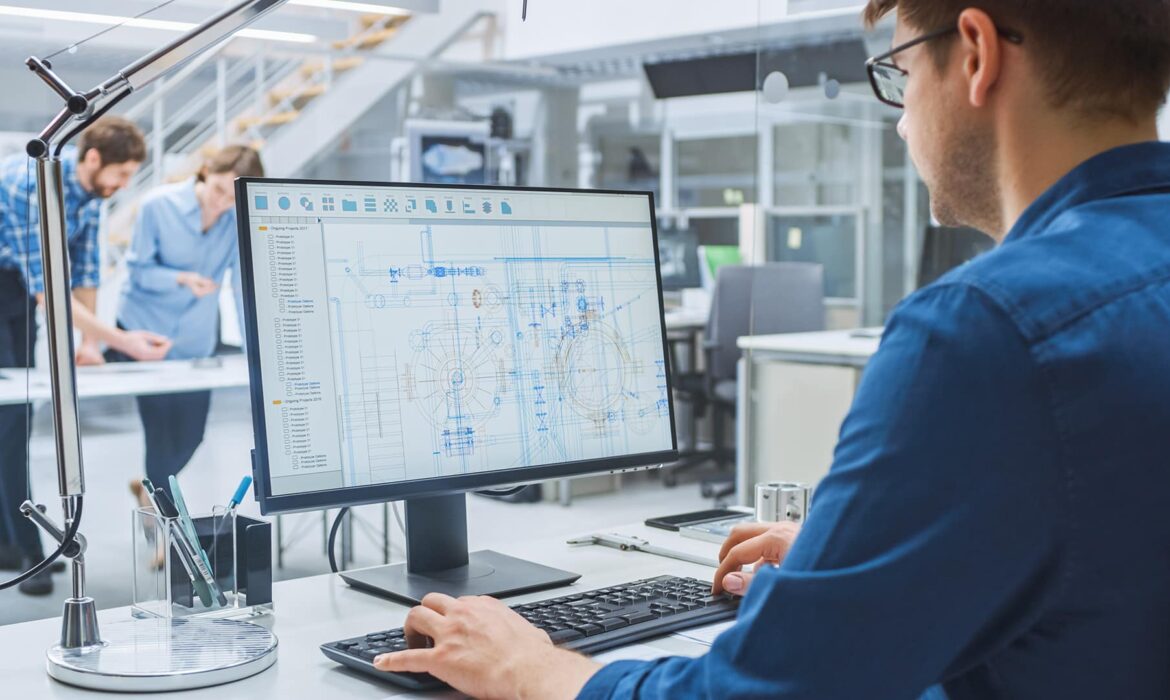

DfX – giving your new product innovation the X factor

When it comes to new product innovation (NPI), there’s no such thing as a one-size-fits-all approach and engineers often find that juggling different priorities leads to costly, late-stage design changes.

Challenging times for A&D supply chains

By developing a ‘digital backbone’ that others can key into, OEMs and Tier One manufacturers can give themselves a competitive edge in collaborative programmes, where end-to-end supply chain integration is required.