Q&A – Cost and Value Engineering

Director Paul Cooper talks to Alan March, our head of cost and value engineering, about this function and the impact that looking at cost through a cost and value engineering lens can have on a business’s operations.

What should it cost? The role of good data

Should Cost modelling is a crucial practice in many industries. However, the key to successful Should Cost modelling is the availability and accuracy of good data.

Designing for X: Optimising costs and other strategic priorities

In this blog we delve into why employing DfX methodology is not just beneficial but critical for optimising costs during new product development projects.

Product cost management – a best practice approach

In today’s business environment, effective cost management is critical for sustaining profitability and competitiveness. We discuss some best practice approaches that can be taken to manage product costs.

The Bottom Line: Effective Methods for Decreasing Product Cost and Boosting Margins

We explain how analysing and challenging Could Cost and Should Cost elements using fact-based models, value engineering and benchmarking can help achieve Best Cost.

Cost and Carbon Reduction through Operational Excellence

Adopting operational excellence can help to achieve both short- and long-term goals across cost and carbon, creating competitive advantage and enabling more effective investment decisions.

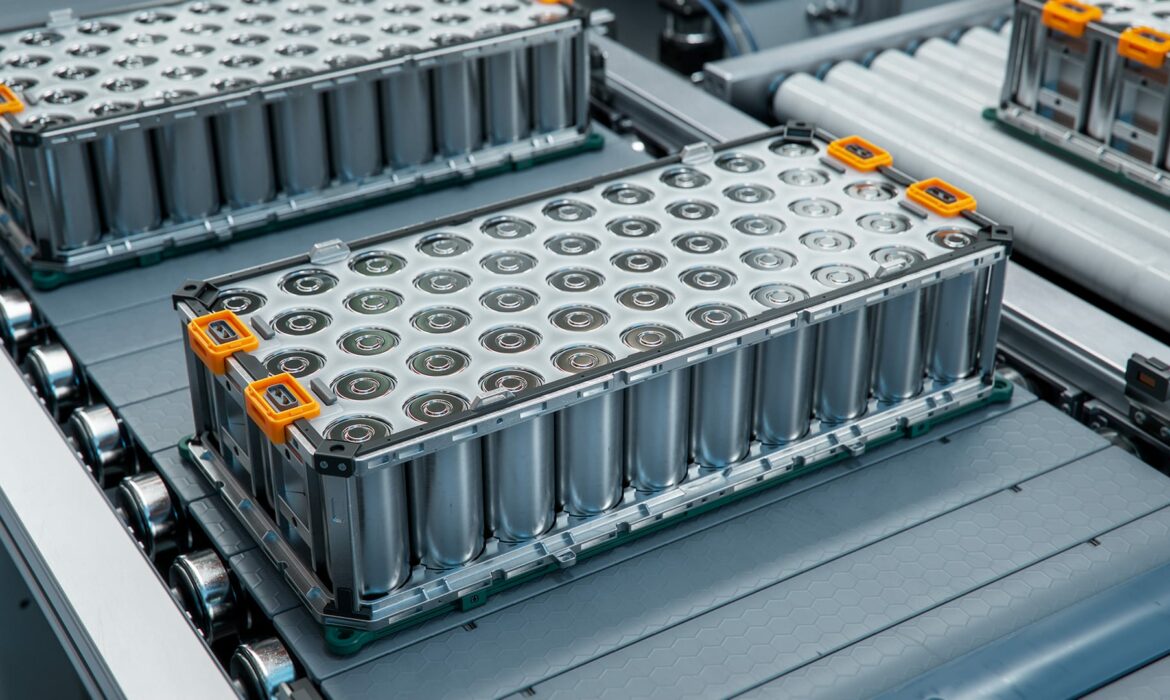

The race to global electrification – Battery Value Chain

We share industry insights across aspects of EV Supply Chain, Battery Manufacturing and Circular economy including what businesses can do to create certainty around business growth.

What’s driving your product and pricing decisions?

Product and pricing decisions are key to survival. But how can a complex business make these decisions amidst so much uncertainty? The answer lies in data understanding.

Creating a competitive advantage in carbon and production cost

Through scenario modeling, the true impact on carbon emissions and product cost can be identified. This can be a competitive advantage to make informed decisions and identify levers that reduce carbon and cost.