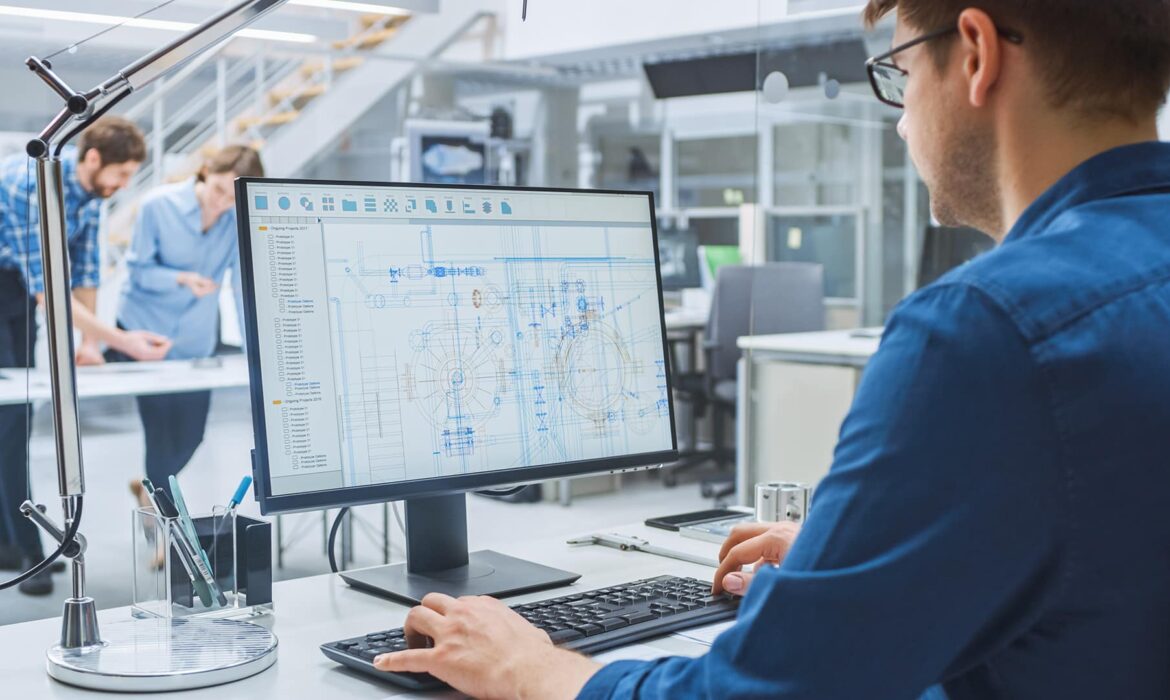

DfX – giving your new product innovation the X factor

When it comes to new product innovation (NPI), there’s no such thing as a one-size-fits-all approach and engineers often find that juggling different priorities leads to costly, late-stage design changes.

Challenging times for A&D supply chains

By developing a ‘digital backbone’ that others can key into, OEMs and Tier One manufacturers can give themselves a competitive edge in collaborative programmes, where end-to-end supply chain integration is required.

How Strategic Initiatives are Transforming the Mining Industry: Taking Major Steps on the Road to Net Zero

The mining industry is taking major steps on its road to Net Zero. In this report we explore the challenges, the opportunities and the 5 steps to create certainty around business growth.

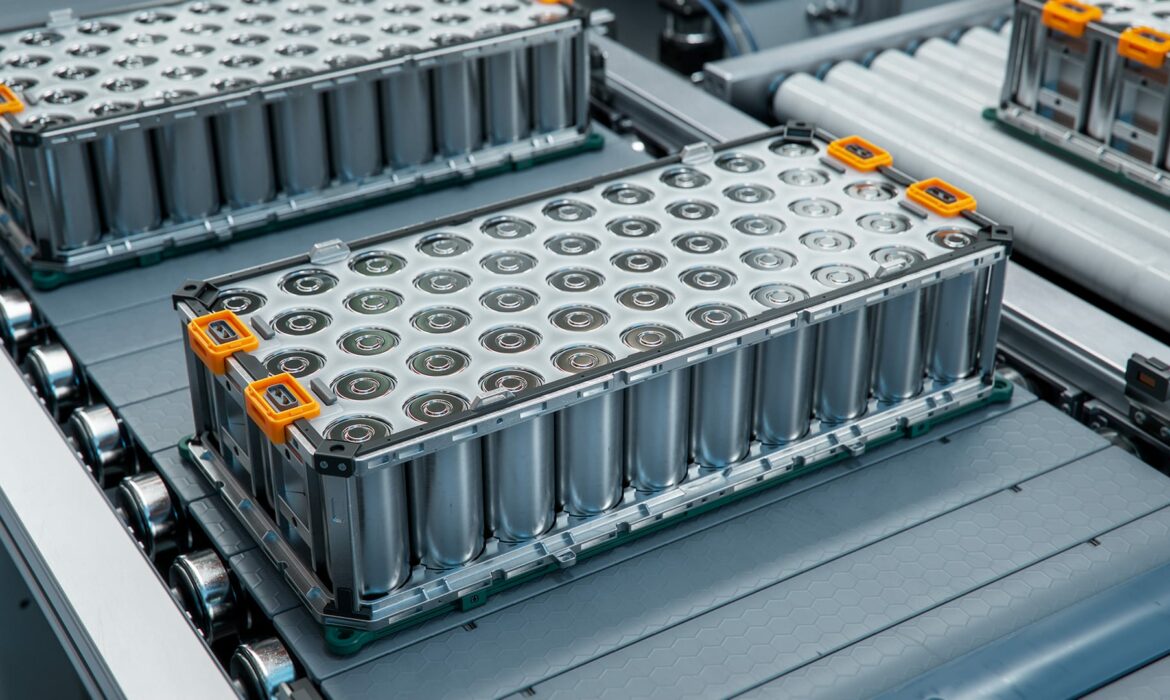

The AI advantage: get ready for battery passports

With greater transparency comes greater responsibility to ensure the supply chain is operating ethically and sustainably.

FMCG manufacturing – data visibility is key to cost and carbon efficiency

An accurate and holistic understanding of the carbon and cost impact of each facet of business operations is imperative to stay competitive.

Where have all the EV incentives gone?

When it comes to deciding whether or not to buy a new battery electric vehicle (BEV), limited access to accurate and reliable user data, as well as a lack of incentives, are holding back sales.

Bringing innovation to life

With product innovation flourishing, manufacturers could be forgiven for innovating first and thinking about whether their value chain is capable of bringing it to market later. Yet taking this approach could be selling themselves short.Using should cost modelling strategies to absorb rising costs

Should Cost modelling can accelerate cost savings, closing the cost gap that often exists between the business environment of months or even years ago, compared to that of today.

Q&A – Cost and Value Engineering

Director Paul Cooper talks to Alan March, our head of cost and value engineering, about this function and the impact that looking at cost through a cost and value engineering lens can have on a business’s operations.