Digital supply chain collaboration is a new deterrent

Ongoing instability has brought pressures for defence industry manufacturers, requiring greater focus on supply chain resilience. Working collaboratively helps to mitigate supply chain risks, while creating a stronger national deterrent.

Fracturing supply chains: where will it end?

It seems that examples of supply chain disruption are all around. What started out as a symptom of the post-Covid ramp-up is now part of the new order, but what is causing all this disruption and will it ever end?

Challenging times for A&D supply chains

By developing a ‘digital backbone’ that others can key into, OEMs and Tier One manufacturers can give themselves a competitive edge in collaborative programmes, where end-to-end supply chain integration is required.

How Strategic Initiatives are Transforming the Mining Industry: Taking Major Steps on the Road to Net Zero

The mining industry is taking major steps on its road to Net Zero. In this report we explore the challenges, the opportunities and the 5 steps to create certainty around business growth.

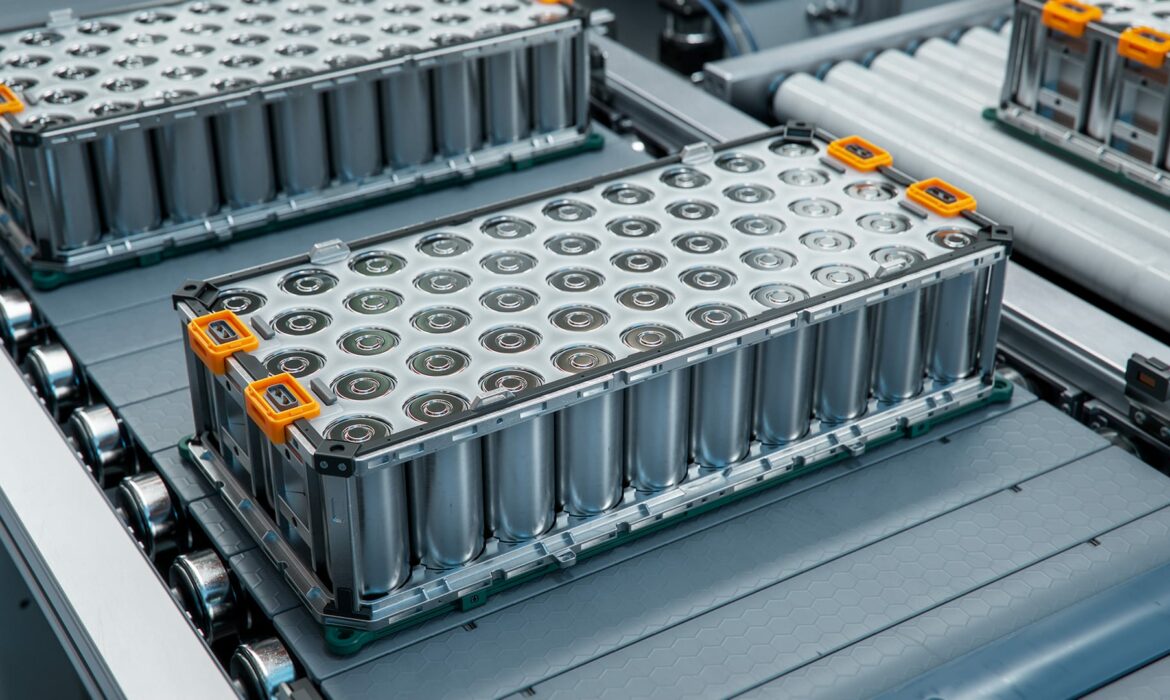

The AI advantage: get ready for battery passports

With greater transparency comes greater responsibility to ensure the supply chain is operating ethically and sustainably.

Where have all the EV incentives gone?

When it comes to deciding whether or not to buy a new battery electric vehicle (BEV), limited access to accurate and reliable user data, as well as a lack of incentives, are holding back sales.

Bringing innovation to life

With product innovation flourishing, manufacturers could be forgiven for innovating first and thinking about whether their value chain is capable of bringing it to market later. Yet taking this approach could be selling themselves short.

Product cost management – a best practice approach

In today’s business environment, effective cost management is critical for sustaining profitability and competitiveness. We discuss some best practice approaches that can be taken to manage product costs.

Speed to market is critical for affordable electric vehicles

With more Chinese electric vehicle makers planning to launch products in the UK in 2024, the race is on for UK and European OEMs to make their mass-market ranges available as quickly as possible.