Putting out fires is necessary, but it won’t deliver growth

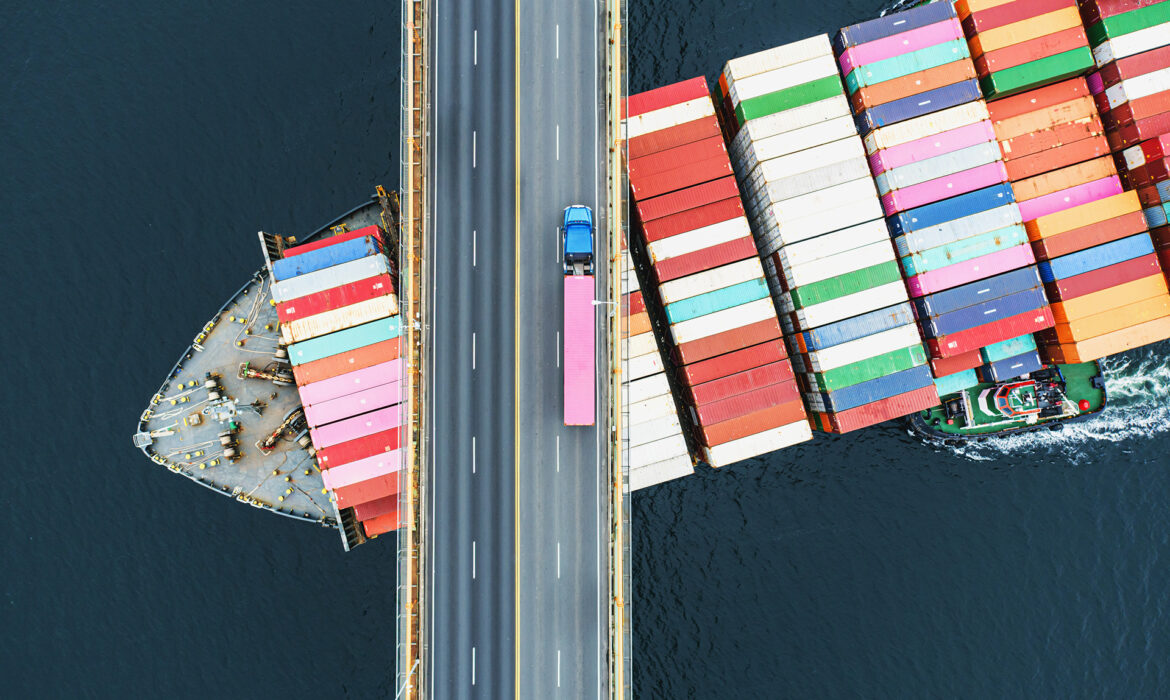

Constantly shifting markets, supply chain disruption, macroeconomic challenges and geopolitical instability are challenging businesses across industry sectors.

Is your organisation prepared for recession?

Economic recession is the latest in a long list of challenges that businesses face at the start of 2023, but are they prepared?

Enabling better supply chain processes and decision-making: Transparent and real-time Total Cost of Ownership

We explore how businesses can utilise their data and deploy technology solutions to enable better process decision-making.

Why 2023 promises great expectations in a value-driven EV market

Price is a key factor for consumers considering an electric vehicle, but there are a range of strategies that manufacturers can adopt to increase market share.

Protean Case Study

Supporting a production-ready BOM through deploying design-to-cost engineering processes.

Industry faces a further push to decarbonise

Are carbon-intensive manufacturers in the aerospace and automotive sectors ready to press ahead with plans to decarbonise their sourcing strategies and production processes?

How to Build Supply Chain Resilience in the Face of Climate Change

Climate change has the potential to cause severe disruption to global supply chains if directors do not plan proactively against it.

3 steps to better supply chain risk management

Here, we look at 3 steps that businesses can take when they’re trying to improve the way they manage risk in the supply chain.

Strategic Demand Planning: 4 best practices you should be following

Demand planning is a crucial process which allows businesses to predict the demands for products or service and manage their operations and supply chain accordingly.