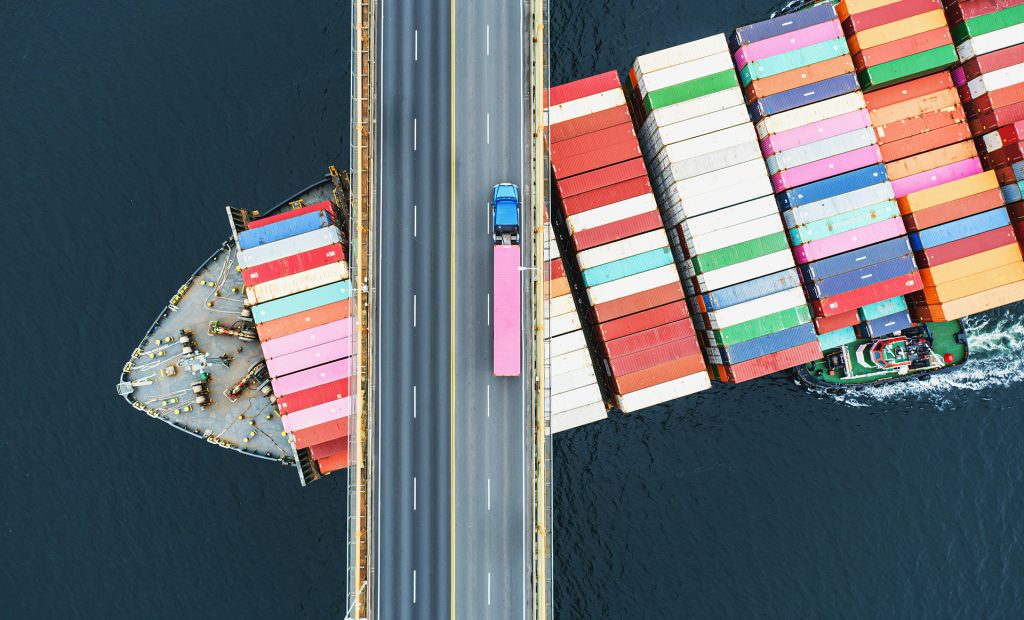

Increasing capacity and meeting decarbonisation goals – can it be done?

We discuss the cost and infrastructure considerations of switching to an all-electric fleet of off-highway vehicles.

At Vendigital our automotive consultants help businesses with complex operations drive cost efficiencies. We’ve partnered with organisations across the whole industry, from manufacturers, OEMs and EV specialists through to automotive retailers and start-ups, helping them to optimise their operations, transform their cost base and create long lasting benefits.

Our automotive consultants understand the unique challenges that are facing the industry. From the rapid switch-over to EVs and the impact that will have on lower servicing demands as well as an increase in the number of leases, to understanding exactly how to take full advantage of “Connected Vehicles”. Our team can provide insights and support on Cost and Value Engineering across new and developing product portfolios and associated supply chain transparency and design, to longer term issues such as increasing use of mobility and car rental services affecting levels of vehicle ownership.

We combine multi-disciplinary consulting expertise and our proprietary digital platform to generate and embed client-specific operational insights, and ultimately deliver data-led accelerated cost transformation. Core to our approach is our deep industry and operational expertise, and in-house data science capability, underpinned by our extensive business transformation and implementation experience.

We take an intelligent approach to cost optimisation and focus on delivering outcomes, not consultancy reports, working with you to execute the plan and deliver quantifiable cost and solutions that deliver long-term results.

We’re witnessing the rapid emergence of new technological advancements and manufacturing capabilities in the industry, particularly in relation to EV and Battery manufacturing underpinned by an increasing rise in global investment.

As such, we have seen increased demand for new types of materials, products, technologies and this demand for manufacturing capabilities and smart technologies to achieve the production level required (an estimated 200 GWh of capacity in the UK alone) is uncovering new sets of supply chain challenges.

Even with the extended net zero target of 2035 for the automotive industry, in order to stay relevant and thrive in tomorrow’s electrified markets, organisations operating in these spaces are looking to address a number of challenges across their supply chain and operations.

Resolutions may not come swiftly or in the short-term, but focus would very much be around introducing agility and resilience in business operations that allows organisations to ride through a supply chain that will remain volatile for some time; at least until technologies and connected capabilities are established, stablised and available enough to create a healthy level of competition.

With an uptick in demand for products and services across all supply chain aspects of this new industry, managing costs and inflationary risks will be key in making Evs affordable and accessible to consumer as well as commercial users/buyers.

At Vendigital, our team of consultants come with a range of backgrounds and industry experience across automotive, manufacturing, and STEM and are able to deploy their considerable industry and operational experience to develop creative solutions to meet these challenges.

• Focus on battery technology can drive supply chain issues, creating inflationary impact and having a knock on effect on accessibility and affordability of EVs

• Hydrogen fuel cells are being studied as an alternative, particularly for the commercial market, although investment in the hydrogen ecosystem doesn’t match that of BEVs

With the entire industry shifting their technology to electrification, two main issues arise:

• The availability of manufacturing equipment and technology, with equipment manufacturers seeing a surge in demand for bespoke capital products as producers look to develop their individual brand of cell chemistries, and

• Availability of skilled workers across all aspects of the supply chain to underpin a new technological boom in this traditionally ageing industry

• A significant increase in demand for electric vehicles, leading to short and medium term production supply chain challenges

• Strain on supply markets can cause shortages and inflationary fluctuations across materials, products and capital equipment which has a bigger macro economic impact

• With an increase in the popularity of car leasing and app-based mobility services, it is becoming more difficult to entice new customers to purchase their own vehicle.

• Disruption to business models as EVs become more widely used by the general public and their perception surrounding the vehicles shifts.

• Affordability in a highly inflationary market and cost of living, become key drivers for decisions around buying and maintaining vehicles with new technology.

Need an automotive sector specialist?

Our automotive consultants combine deep expertise in supply chain management, portfolio management and cost engineering, as well as data science and business transformation. As experts in the automotive industry, with many having previously worked for automotive businesses at the coal face, they have the knowledge, skills and experience to deliver measurable cost benefits across your operations.

By bringing together our multi-disciplinary consulting expertise with our digital platform, we are able to deploy data-driven operational insights to embed measurable and sustainable cost benefits across your business.

We do this across:

Our team of automotive consultants will work with you to identify cost optimisation opportunities, both quick win and longer-term. This may include remodelling the operating strategy to ensure that the structure of the business reflects its current needs and challenges, and that the costs to the business are minimised by assessing factors such as the footprint of manufacturing locations. Reviews can be conducted into the various price points and lead times across the supply chain to model and understand what’s driving cost, so that improvements can be made. We also work with automotive retailers to optimise the way they procure 3rd party services, with the goal of streamlining their supply chain and maximising the value they get from their cost base.

From manufacturing queries to sourcing design issues, cost-modelling, and operational performance improvements, we work as part of your team, engaging with stakeholders and suppliers to develop a targeted programme to deliver cost efficiencies at pace.

Get in touch to find out how we can partner with you to achieve your cost transformation requirements.

We are ideally placed to help complex businesses accelerate the transformation of their cost bases.

Client collaboration is at the heart of our approach

We cut through complexity quickly

We're focused on delivering long-term outcomes for clients

We work with clients to set the strategy and deliver the nuts and bolts of the solution

Intelligent approach to cost optimisation through deep understanding of cost and cost drivers

Deliver quantifiable cost reductions through our cost neutral fee structure

We discuss the cost and infrastructure considerations of switching to an all-electric fleet of off-highway vehicles.

EV makers in the UK and Europe are warning that Zero Emission Mandates are simply not doable and subdued levels of demand could force them to close factories. Should the industry embrace Chinese capability before it’s too late?

In our latest report we examine the impact of power electronics and the importance of inverters in EV manufacturing.