Collaboration key to managing supply shocks

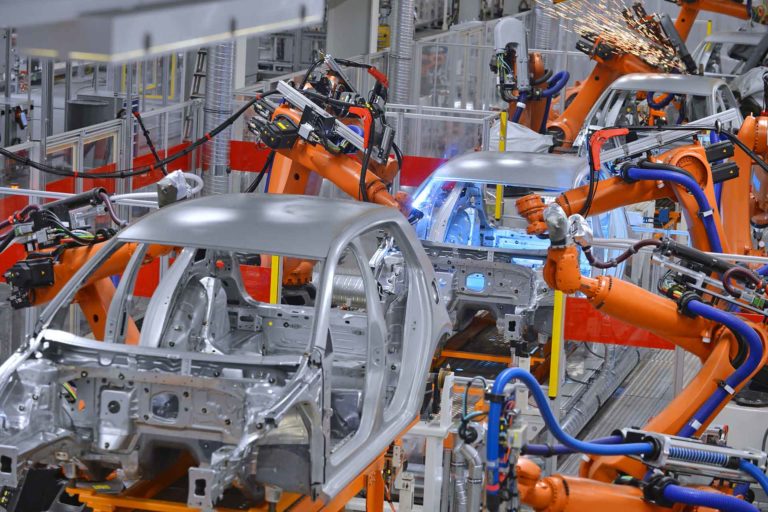

Manufacturers need to collaborate closely with suppliers to mitigate the impact of shocks and supply chain disruptions.

Combining our deep operational and industry expertise, and in-house data science capability, our insights provide fresh perspectives and practical guidance to help businesses address the complex operational challenges and issues they face.

Manufacturers need to collaborate closely with suppliers to mitigate the impact of shocks and supply chain disruptions.

By reviewing inventory management across the value chain, there could be an opportunity to right size stock and optimise much-needed working capital.

Ongoing instability has brought pressures for defence industry manufacturers, requiring greater focus on supply chain resilience. Working collaboratively helps to mitigate supply chain risks, while creating a stronger national deterrent.

By developing a ‘digital backbone’ that others can key into, OEMs and Tier One manufacturers can give themselves a competitive edge in collaborative programmes, where end-to-end supply chain integration is required.

In the midst of a ramp up in production, many manufacturers have been adding stock buffers. However, holding more stock has impacted inventory turn performance and eroded working capital.

By harnessing digital technologies, manufacturers can create factories and supply chains that are green, lean and equipped to deliver what industries need now and in the future.

Nick Harrison, Partner and Head of Consulting at Vendigital, outlines how closing the gaps in business data can help organisations answer to a diverse set of stakeholders.

Constantly shifting markets, supply chain disruption, macroeconomic challenges and geopolitical instability are challenging businesses across industry sectors.

With consulting firms functioning increasingly as partners, rather than simply advisors, there is more pressure than ever from clients to demonstrate long-term gains via engagements.

Supply chain deficits, such as semiconductor and chip shortages, have had a huge impact on businesses in recent years.

The UK car industry may be falling behind its competitors, but with joined-up thinking and investment from manufacturers, industry bodies and the government it’s not too late to for it to catch up.

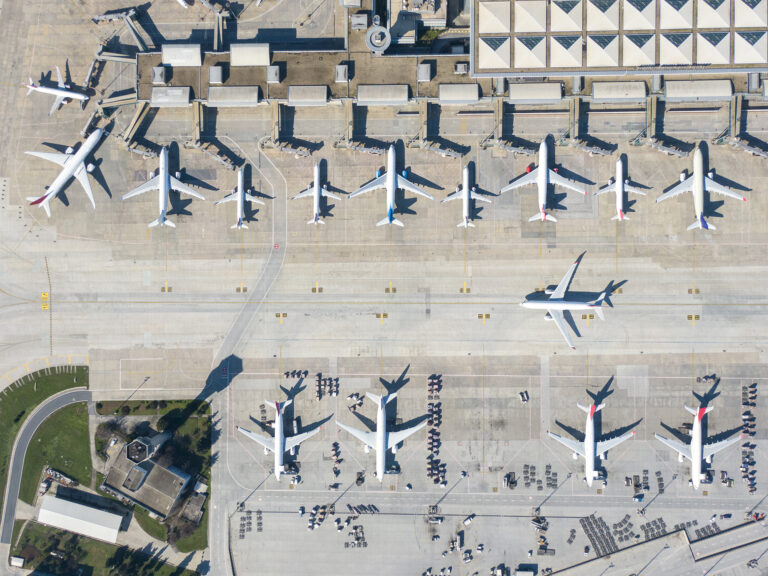

At a time when many aerospace manufacturers have been struggling to restore their productivity in the wake of the Covid-19 pandemic, the ramp-up challenge is adding pressure to an already demanding situation.

Matthew Flynn discusses how transformation of the rail industry’s approach to seat utilisation could benefit both the TOCs and passengers.

Julie Neal and Alex Copeland explain how by working collaboratively both sides of the negotiating table can avoid clashes and potentially generate added value too.

Chief Operating Office Emma Charsley shares her experience and how she is helping to promote diversity and inclusion in the professional services sector.

During the pandemic, it became clear that traditional modelling techniques could not be relied upon to predict levels of demand. So, how can organisations adapt to a climate of demand uncertainty?

Vendigital has been announced as a five time finalist across the following categories: Commercial Impact, Rising Star, Experienced Leader Award and Lifetime Achievement Award.

Analysis of ORR figures show staff represent 35% of the costs of running the UK’s railways. Implementing efficient staffing strategies is key to unlocking cost savings and securing a sustainable future for the industry.

Brexit and the Covid-19 pandemic continue to affect organisations across the business landscape. Decision-makers must find ways to live with disruption by adapting their business models, while controlling costs.

With so much venture capital up for grabs, electric vehicle (EV) start-ups and other tech companies in the sector have arguably never faced a better opportunity to fast-forward their strategic growth plans.

At a time when inflation is rising and supply shortages are impacting productivity, cost control has never been more important. So, how can manufacturers go about optimising costs when operating in uncertain markets?

In this white paper we look at how business can better balance their customers changing needs with their own operational requirements.

Our white paper shares insights on what stage of digital transformation UK manufacturers have reached, the benefits and a digital transformation roadmap.

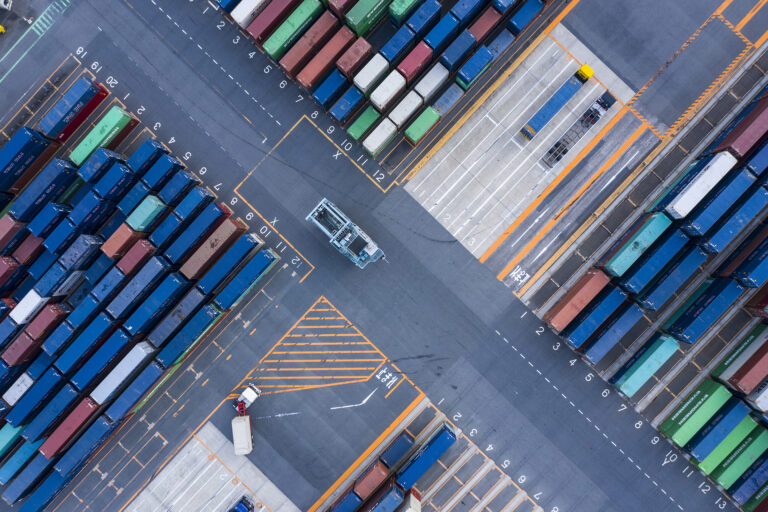

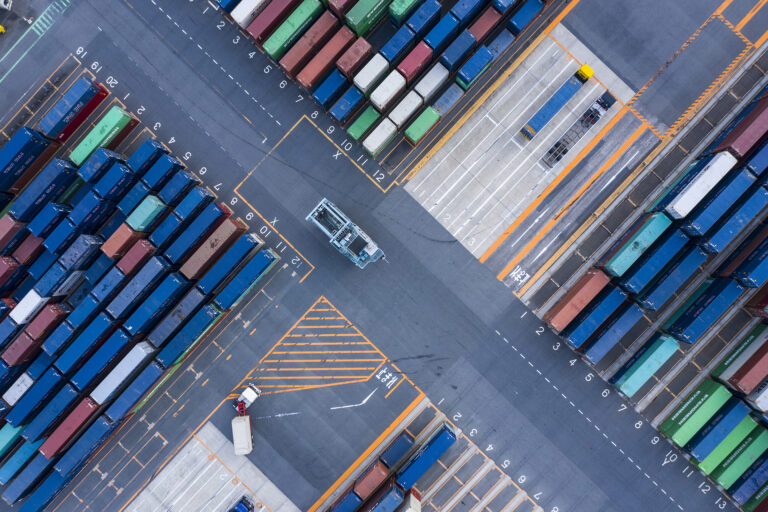

Recent high-profile events have served to highlight how vulnerable many supply chains are. We examine how to build supply chain resilience and translate this into competitive advantage.

Long-standing low and recently falling margins in construction are in danger of becoming an expected norm. But does it really have to be that way?

The challenges and benefits of building supply chain resilience and how businesses should look to future proof their supply chain as an enabler of competitive advantage.

The pandemic has provided a

reminder of just how unpredictable patterns of supply and demand can be. Customers now expect a rapid, demand-driven approach to order fulfilment.

Vendigital has hired an experienced industry expert to work in the A&D sector to support expansion and compliment the incumbent team

Justin Benson discusses the importance of ongoing supply chain assessment, highlights some of the challenges involved and outlines how businesses can look to do this effectively.

Inspirational examples of innovation in response to shifts in market demand have been a stand-out feature of the past year, with many manufacturers pivoting to focus on revenue generation during the pandemic

Stay connected

Stay up to date with Vendigital by signing up to our email newsletter.