Balancing risk and reward is key to sustainable growth during recession

As manufacturers strive to protect revenues and maintain market position, balancing risk and reward could enable them to achieve growth.

Diffuse inflation pressures

The geopolitical climate has become more volatile in recent times, putting pressure on global supply chains and triggering inflation. For manufacturers, this has led to a build-up of inflationary pressures, all of which need diffusing now.

How digital twin tech can improve cost predictability

The effective use of digital twin technology can help UK manufacturers take back control of costs through faster, more agile decision making.

Five steps to a fully integrated value chain

By following these five steps, businesses can boost their productivity and increase profits at each link in the chain.

Prepare for prolonged high inflation

Rising energy and prices are forcing UK manufacturers to increase prices, but there is a limit to how far they can go. With inflationary pressures increasing, they need to consider alternative strategies.

COP26: A data-driven approach to developing a net zero roadmap

While many businesses have set out on their net zero journeys, others are just getting started. Either way, the pressure on Boards to take action is mounting and planning for net zero has risen up the agenda.

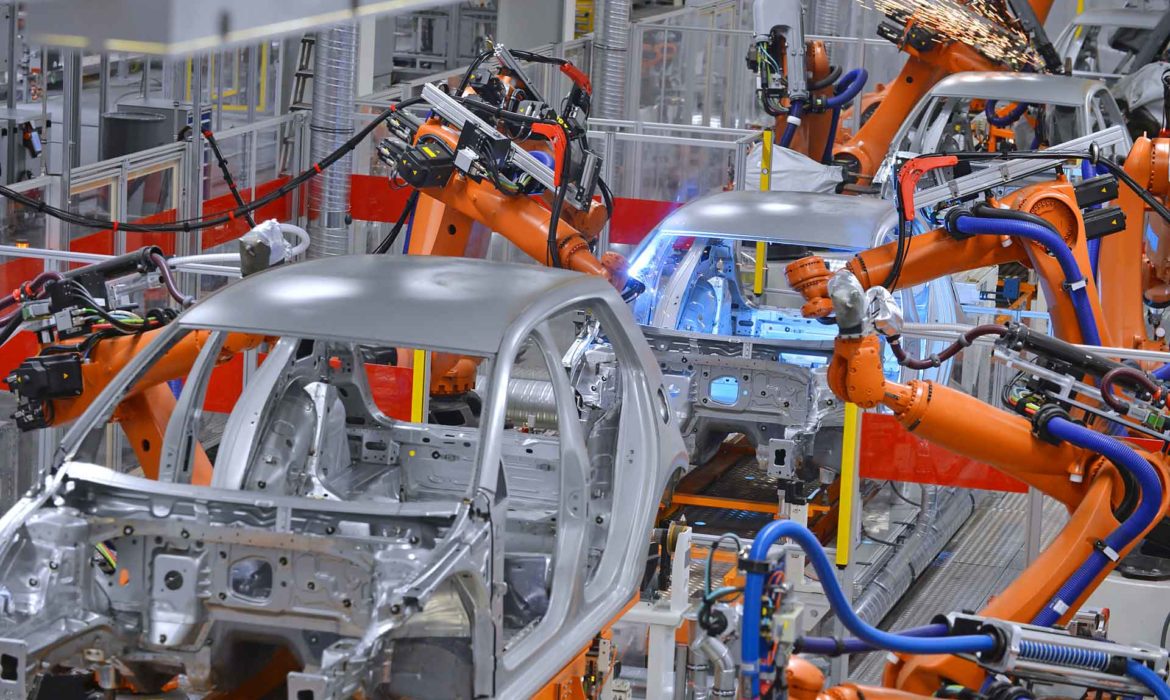

Managing supply and demand in a high-risk world

At a time when inflation is rising and supply shortages are impacting productivity, cost control has never been more important. So, how can manufacturers go about optimising costs when operating in uncertain markets?

Don’t Let Rising Prices Curb Your Recovery

Rising inflation is adding to the pressure on manufacturers. Rather than allowing inflation to erode margins, businesses must decide whether to pass the increase onto customers or reduce their cost base.

Decarbonisation: a defining moment for carbon-intensive industries

To plot their path to net-zero, businesses will need to instigate a bespoke decarbonisation roadmap and demonstrate their willingness to adapt their operations and systems.