Increasing capacity and meeting decarbonisation goals – can it be done?

We discuss the cost and infrastructure considerations of switching to an all-electric fleet of off-highway vehicles.

Combining our deep operational and industry expertise, and in-house data science capability, our insights provide fresh perspectives and practical guidance to help businesses address the complex operational challenges and issues they face.

We discuss the cost and infrastructure considerations of switching to an all-electric fleet of off-highway vehicles.

EV makers in the UK and Europe are warning that Zero Emission Mandates are simply not doable and subdued levels of demand could force them to close factories. Should the industry embrace Chinese capability before it’s too late?

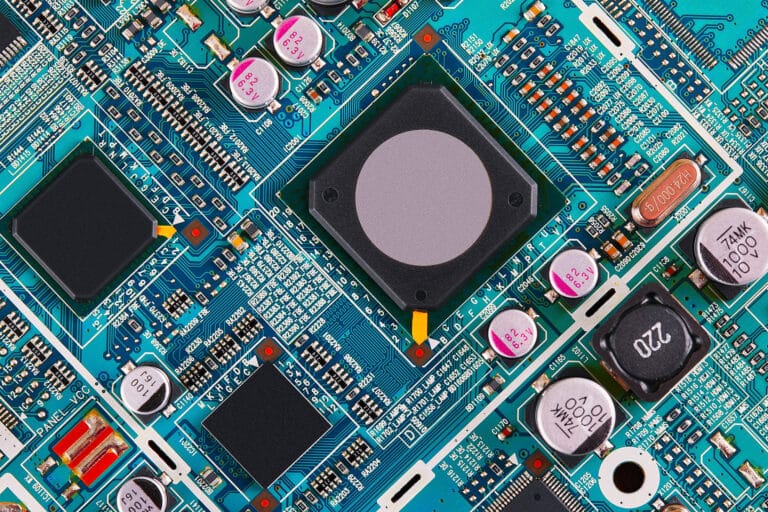

In our latest report we examine the impact of power electronics and the importance of inverters in EV manufacturing.

Automakers are facing a dilemma – with demand for hybrid cars burgeoning but having already invested in building pure EV platforms, what should they do now?

The EU commission has also stated that it is “open to a mutually acceptable solution” on the subject of Chinese EV imports. While a path to agreement is likely to take time, it could be a win-win for the EU and China.

Used EVs are now attracting residual values close to those of used ICE vehicles. However, barriers to sale remain, with many consumers still concerned about access to charging infrastructure and total running costs.

The mining industry is taking major steps on its road to Net Zero. In this report we explore the challenges, the opportunities and the 5 steps to create certainty around business growth.

With greater transparency comes greater responsibility to ensure the supply chain is operating ethically and sustainably.

When it comes to deciding whether or not to buy a new battery electric vehicle (BEV), limited access to accurate and reliable user data, as well as a lack of incentives, are holding back sales.

With more Chinese electric vehicle makers planning to launch products in the UK in 2024, the race is on for UK and European OEMs to make their mass-market ranges available as quickly as possible.

As climate targets approach manufacturers could be doing more to tackle Scope 2 emissions – resulting from the generation of purchased energy – and Scope 3 emissions – produced throughout the whole value chain.

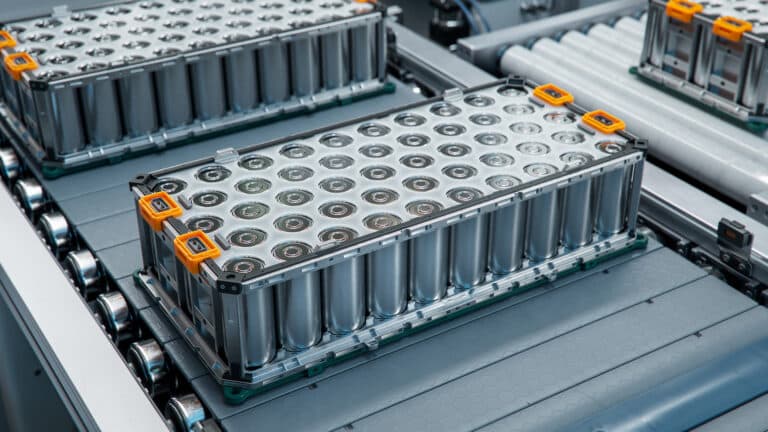

With EV battery packs and raw materials in short supply, it is critical for manufacturers to improve operational resilience and secure the supplies they need.

We share industry insights across aspects of EV Supply Chain, Battery Manufacturing and Circular economy including what businesses can do to create certainty around business growth.

The proposed delay to the introduction of the new rules of origin is a window of opportunity for UK and European carmakers.

As the market for used electric vehicles starts to mature, the condition of the battery that accounts for much of a car’s value is becoming an important factor in buying decisions.

The rise of the car subscription model is an opportunity for traditional car makers and EV platforms alike to drive revenues in a challenging market.

The latest data on new vehicle registrations in the UK shows that sales of electric vehicles are now rising at a record rate, and this segment of the market is set to be the main driver of sales in 2023.

The UK car industry may be falling behind its competitors, but with joined-up thinking and investment from manufacturers, industry bodies and the government it’s not too late to for it to catch up.

This guide has been created best practices specific to the sourcing of LIBs, to help EV manufacturers identify the right supplier partner and achieve the optimal technical and commercial outcomes.

Price is a key factor for consumers considering an electric vehicle, but there are a range of strategies that manufacturers can adopt to increase market share.

Many dealerships and independent services centres are facing pressures due to inflation and supply chain disruption. Could they be doing more to engineer their way to a more stable and profitable future?

Are carbon-intensive manufacturers in the aerospace and automotive sectors ready to press ahead with plans to decarbonise their sourcing strategies and production processes?

Removing the cost of battery ownership from the equation could help boost mass market uptake of electric vehicles.

Innovative approaches are helping automotive manufacturers get ahead in the race to achieve net-zero emissions by 2050. But could the sector decarbonise faster.

Embryonic battery chemistries and related technologies are helping to shape tomorrow’s global electric vehicle (EV) market. But will they come quickly enough to meet consumer demand?

In the final video in our series providing an overview of the EV market, we look at the challenges the EV market needs to overcome.

In the second of a series of three videos providing an overview of the EV market, we look at what is forecasted in coming years.

In the first of a series of three videos providing an overview of the EV market, we look back at the EV market in 2021.

The prospect of an extended armed conflict in Ukraine means manufacturers of electric vehicles need to find alternative sources of vital raw materials and components.

As the auto industry eyes high growth in EVs ahead, what does that mean for supply chains?

Stay connected

Stay up to date with Vendigital by signing up to our email newsletter.