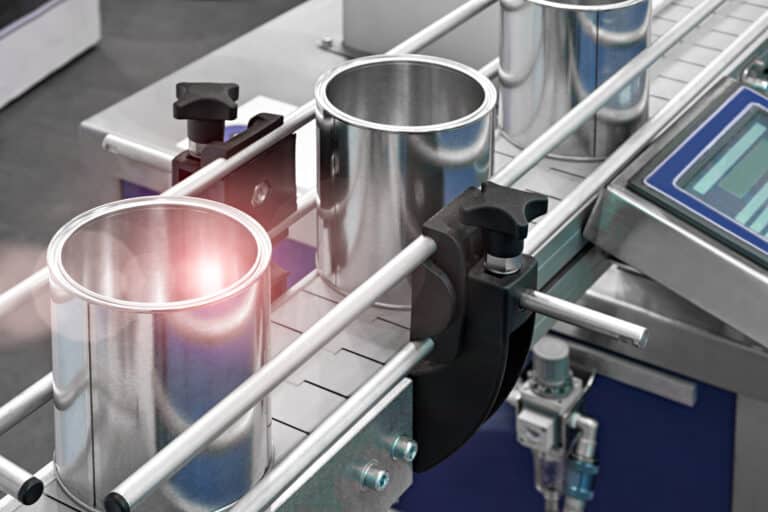

Bringing innovation to life

With product innovation flourishing, manufacturers could be forgiven for innovating first and thinking about whether their value chain is capable of bringing it to market later. Yet taking this approach could be selling themselves short.