Removing and controlling costs – a strategic imperative for construction firms

Long-standing low and recently falling margins in construction are in danger of becoming an expected norm. But does it really have to be that way?

Supply chain understanding and development is key to retrofit success

Action is needed to upgrade the energy efficiency homes and other buildings in the UK. However, issues must be addressed to implement the retrofit programme.

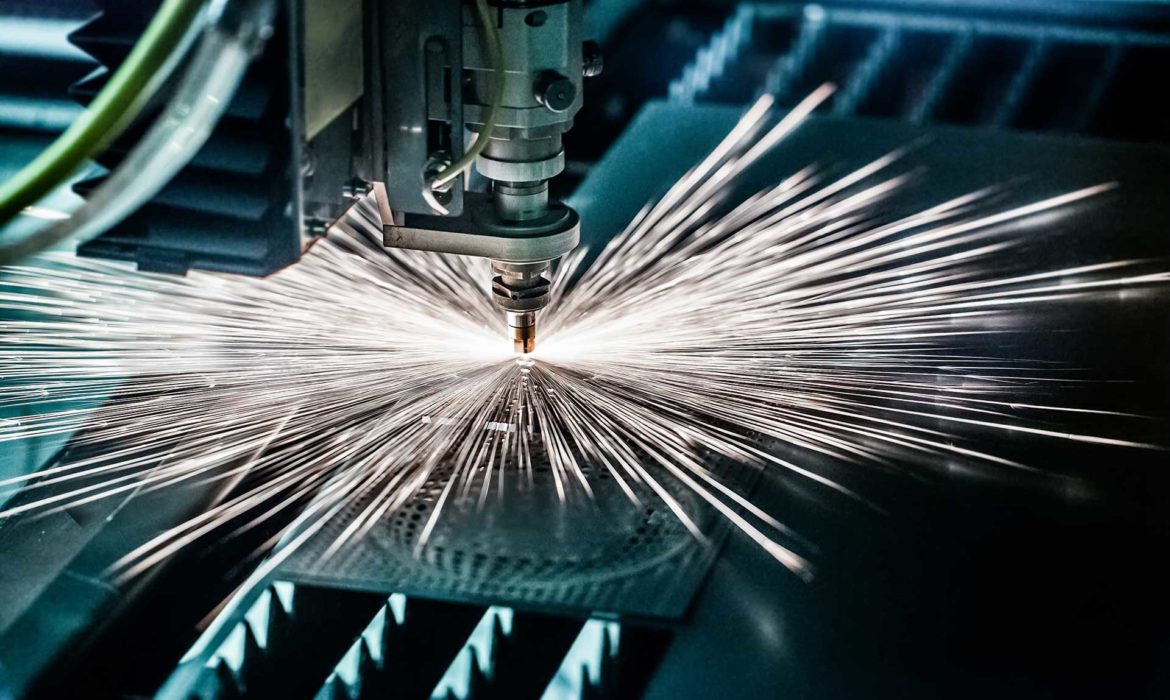

Supply chain challenges emerging from the pandemic and how to build resilience

In this video, we explore the supply chain challenges emerging from the pandemic and how businesses can build resilience into their operations.

Prioritising supply chain resilience is key to recovery

Many manufacturers have faced significant supply chain disruption over the past year. By focusing on improving supply chain resilience there is an opportunity for OEMs to position themselves for growth and profits.

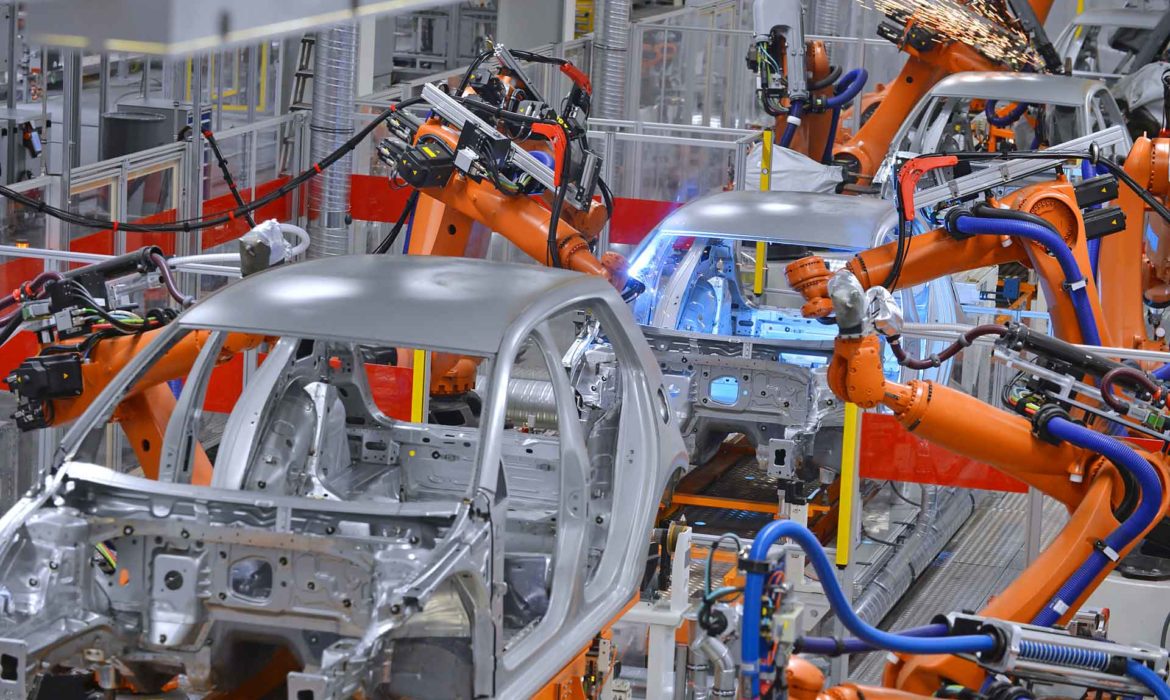

Will 2021 be the year supply problems hit car manufacturing?

A shortage of semiconductors resulting from the Covid-19 pandemic could be a watershed moment for automotive OEMs who are willing to adapt to the situation.

What’s changed for global supply chain strategy?

But with the prospect of COVID-19 vaccines in the pipeline, are supply chain and procurement managers preparing to press the reset button, or have global supply chain strategies changed for good?

Preparing for a hydrogen-fuelled future

Why is there so much excitement about hydrogen’s potential for transforming the sustainability of modern air travel, and what practical challenges stand in the way of aviation’s hydrogen-fuelled future?

Is car ownership back in the driving seat?

Some analysts believe the car ownership model could soon be back in the ascendancy due to COVID-19. What impact is this having on the automotive industry and are there any supply chain implications?

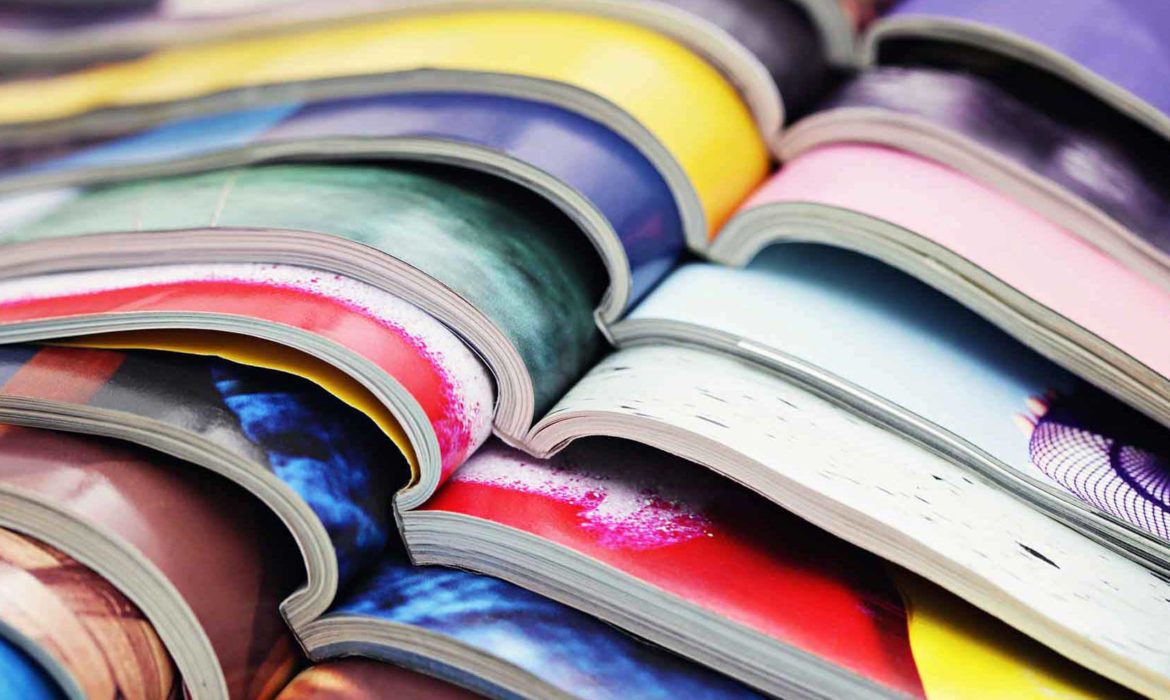

TI Media Case Study

In a rapidly-shifting marketplace with declining traditional revenue streams, the business needed to invest in growth areas by reducing the cost base of core brands, whilst protecting product quality.