Putting factory-based production in the spotlight

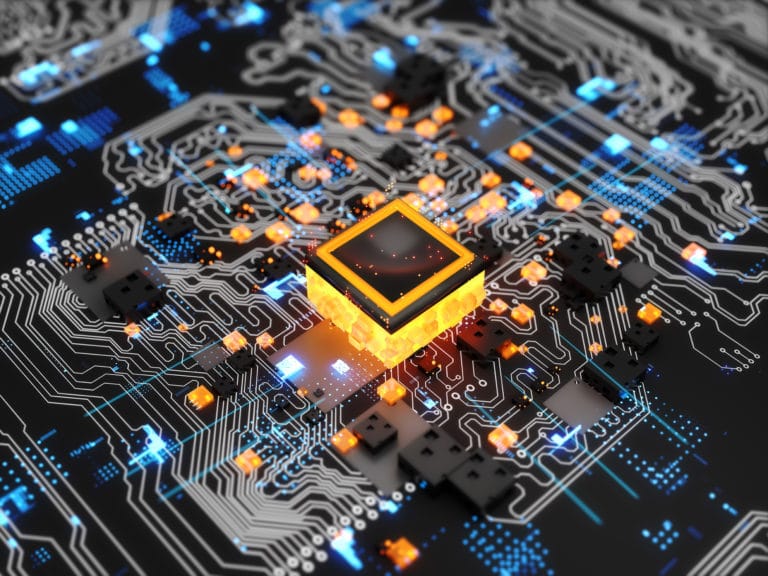

Are manufacturers prioritising investment in digital capability and Industry 4.0 technologies?

Combining our deep operational and industry expertise, and in-house data science capability, our insights provide fresh perspectives and practical guidance to help businesses address the complex operational challenges and issues they face.

Are manufacturers prioritising investment in digital capability and Industry 4.0 technologies?

With the government’s renewed focus on upgrading national infrastructure, clean energy providers must ensure their supply chains and processes are fully optimised ahead of any increased demand.

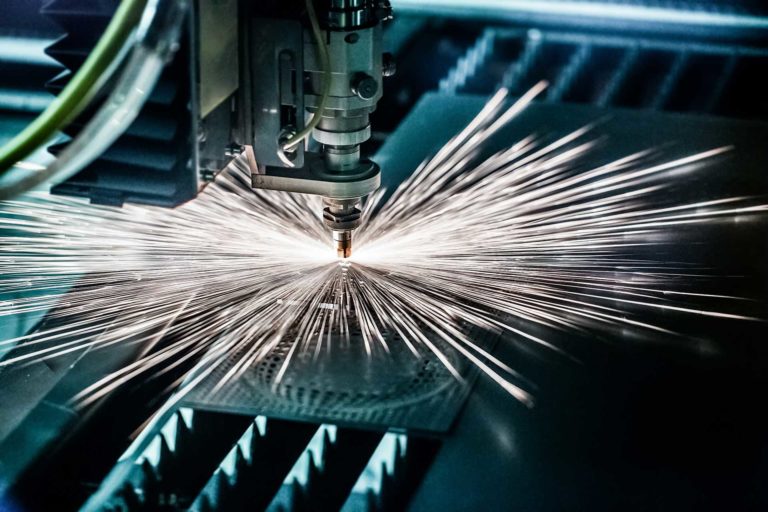

When it comes to new product innovation (NPI), there’s no such thing as a one-size-fits-all approach and engineers often find that juggling different priorities leads to costly, late-stage design changes.

Should Cost modelling can accelerate cost savings, closing the cost gap that often exists between the business environment of months or even years ago, compared to that of today.

Should Cost modelling is a crucial practice in many industries. However, the key to successful Should Cost modelling is the availability and accuracy of good data.

In this blog we delve into why employing DfX methodology is not just beneficial but critical for optimising costs during new product development projects.

In today’s business environment, effective cost management is critical for sustaining profitability and competitiveness. We discuss some best practice approaches that can be taken to manage product costs.

We explain how analysing and challenging Could Cost and Should Cost elements using fact-based models, value engineering and benchmarking can help achieve Best Cost.

As climate targets approach manufacturers could be doing more to tackle Scope 2 emissions – resulting from the generation of purchased energy – and Scope 3 emissions – produced throughout the whole value chain.

With technology, including Artificial Intelligence (AI), advancing at a faster pace than ever before, businesses must have strategies in place to utilise it effectively or risk falling behind.

As manufacturers strive to protect revenues and maintain market position, balancing risk and reward could enable them to achieve growth.

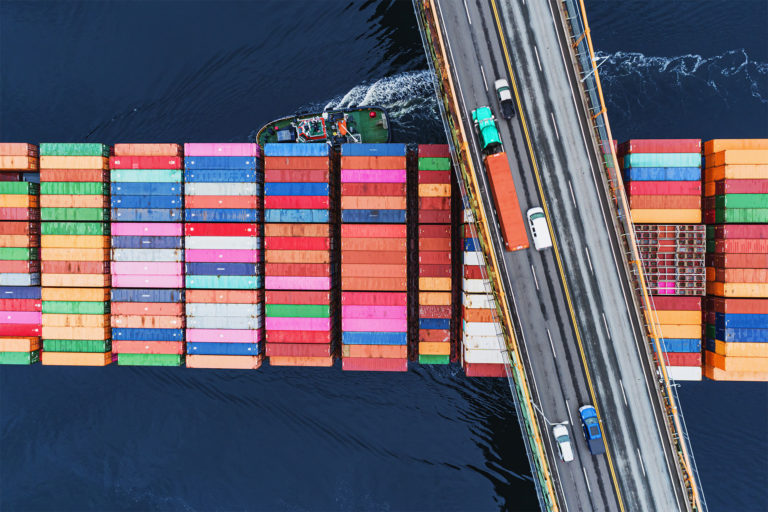

The geopolitical climate has become more volatile in recent times, putting pressure on global supply chains and triggering inflation. For manufacturers, this has led to a build-up of inflationary pressures, all of which need diffusing now.

The effective use of digital twin technology can help UK manufacturers take back control of costs through faster, more agile decision making.

By following these five steps, businesses can boost their productivity and increase profits at each link in the chain.

Rising energy and prices are forcing UK manufacturers to increase prices, but there is a limit to how far they can go. With inflationary pressures increasing, they need to consider alternative strategies.

While many businesses have set out on their net zero journeys, others are just getting started. Either way, the pressure on Boards to take action is mounting and planning for net zero has risen up the agenda.

At a time when inflation is rising and supply shortages are impacting productivity, cost control has never been more important. So, how can manufacturers go about optimising costs when operating in uncertain markets?

Rising inflation is adding to the pressure on manufacturers. Rather than allowing inflation to erode margins, businesses must decide whether to pass the increase onto customers or reduce their cost base.

To plot their path to net-zero, businesses will need to instigate a bespoke decarbonisation roadmap and demonstrate their willingness to adapt their operations and systems.

Inspirational examples of innovation in response to shifts in market demand have been a stand-out feature of the past year, with many manufacturers pivoting to focus on revenue generation during the pandemic

Many manufacturers have faced significant supply chain disruption over the past year. By focusing on improving supply chain resilience there is an opportunity for OEMs to position themselves for growth and profits.

But with the prospect of COVID-19 vaccines in the pipeline, are supply chain and procurement managers preparing to press the reset button, or have global supply chain strategies changed for good?

Despite some tentative signs of manufacturing sector recovery, cost reduction strategies remain a key focus for many businesses and could make the difference between success or failure in the months ahead.

Onshoring could prove a rewarding post-pandemic recovery strategy for many UK-based OEMs, but are they ready to take advantage of this value-driving opportunity?

The Covid-19 pandemic has had a cataclysmic effect across all sectors, forcing manufacturers to react quickly to continue to meet market demand. In the first of a series

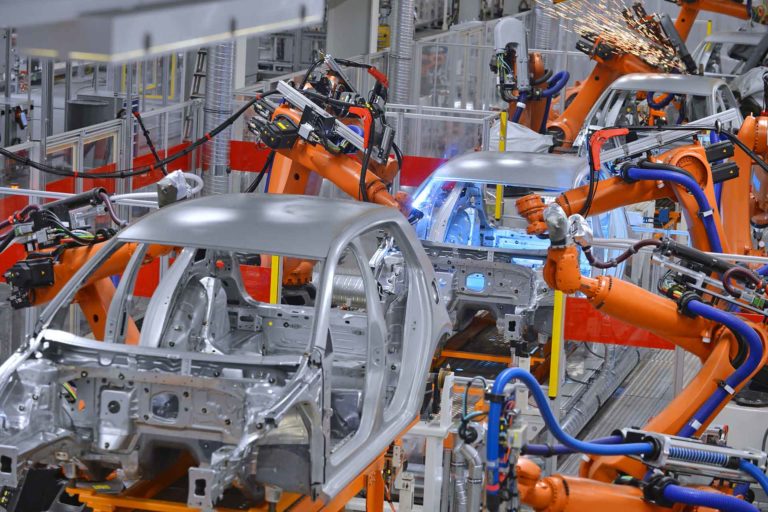

The manufacturing sector’s adoption of robotics is on the rise. However, when faced with a wide range of collaborative automation technologies, how do businesses know which to choose and how can they optimise value from their investment?

In an era calling for latency-sensitive applications, where the emergence of edge computing, 5G and AI powered analytics are ushering in the possibility of real-time solutions, companies are looking for the most efficient ways to make use of data.

Accessing and organising data, which is both reliable and capable of delivering valuable business insights, is a constant challenge for high-value manufacturers.

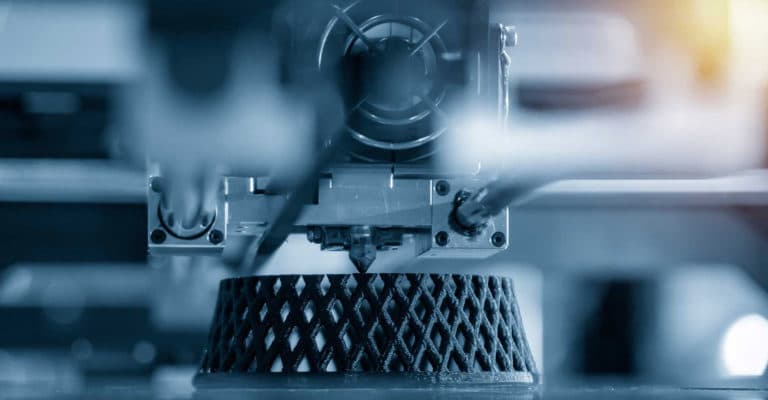

Dominic Tribe explains how production-oriented prototyping can help reduce costs and risks for manufacturers by integrating design resources.

Jaguar Land Rover (JLR) has called for the creation of multiple ‘gigafactories’ to provide the large volume of batteries needed to fuel its electrification strategy.

Stay connected

Stay up to date with Vendigital by signing up to our email newsletter.