Building supply chain agility is now more critical than ever

The pandemic has provided a reminder of just how unpredictable patterns of supply and demand can be. Customers now expect a rapid, demand-driven approach to order fulfilment.

Robust, ongoing supply chain assessment is a critical underpin to strategic decision-making

Justin Benson discusses the importance of ongoing supply chain assessment, highlights some of the challenges involved and outlines how businesses can look to do this effectively.

Is car ownership back in the driving seat?

Some analysts believe the car ownership model could soon be back in the ascendancy due to COVID-19. What impact is this having on the automotive industry and are there any supply chain implications?

The long road to recovery starts here

With airlines grounded and international travel restrictions only now beginning to lift slightly, demand for replacement aircraft has plummeted and could take several years to recover.

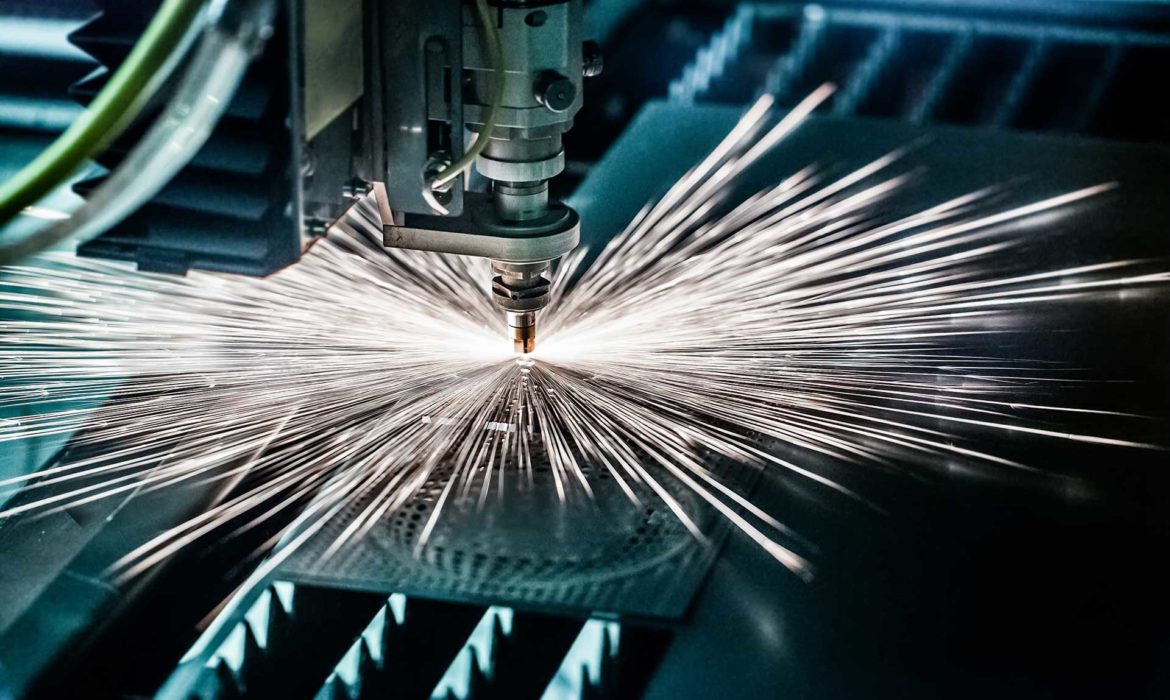

Onshoring could be a valuable post-pandemic strategy

Onshoring could prove a rewarding post-pandemic recovery strategy for many UK-based OEMs, but are they ready to take advantage of this value-driving opportunity?

It’s time to pivot in favour of EVs

As automotive supply chains start up again, OEMs have important choices to make about how they rebuild their operations. Has the time come to ‘bet the house’ and invest in the battery electric future?

COVID-19: Supply chain focus is key to automotive industry recovery

Vehicle manufacturers and Tier 1 and 2 component manufacturers should avoid severing relationships with businesses further down their supply chains and look for ways to support them on the way to recovery. Doing so could give them a competitive advantage as the pandemic starts to subside.

COVID-19: Planning for recovery

As OEMs cut production rates and MRO volumes drop sharply, manufacturers must plan their next move carefully. Paul Adams, Head of Aerospace & Defence, examines what steps companies can take to plan for the post-COVID-19 landscape.

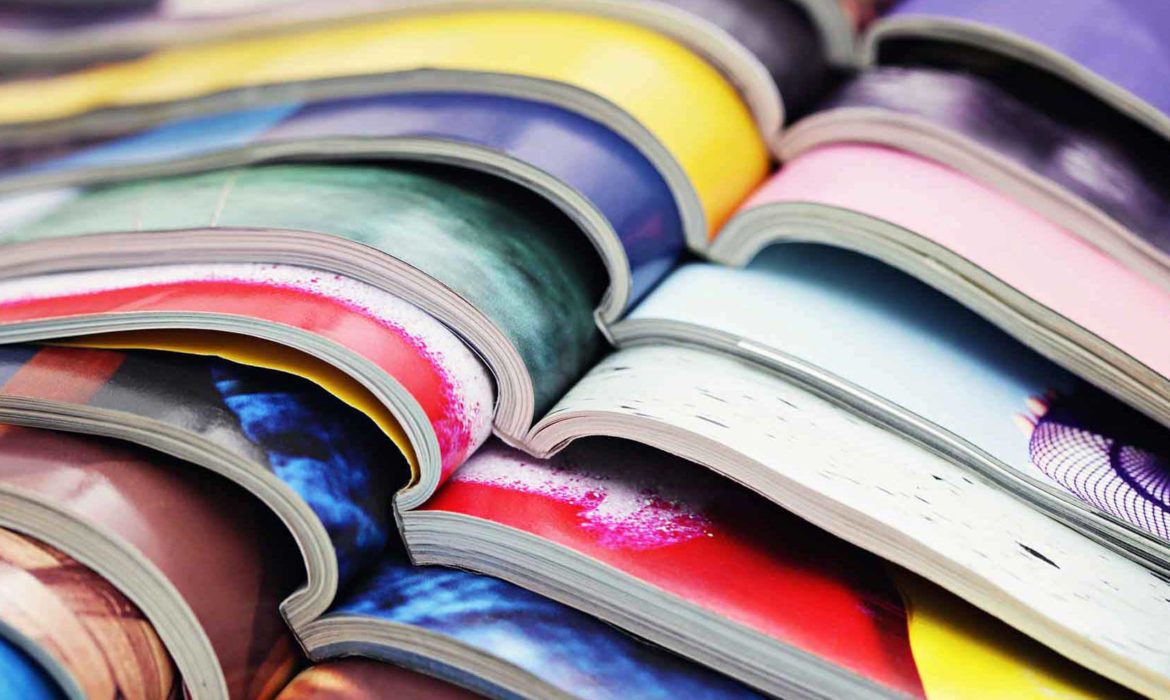

Marketforce Case Study

How the appliance of exceptional data science transformed the business strategy decision-making for a leader in UK wholesale distribution.