More EVs are coming, but will the price be right?

Justin Benson considers the importance of balancing brand and price as established car makers line up to launch new mass market EVs.

Baking in value on the road to industrialisation

Inspirational examples of innovation in response to shifts in market demand have been a stand-out feature of the past year, with many manufacturers pivoting to focus on revenue generation during the pandemic

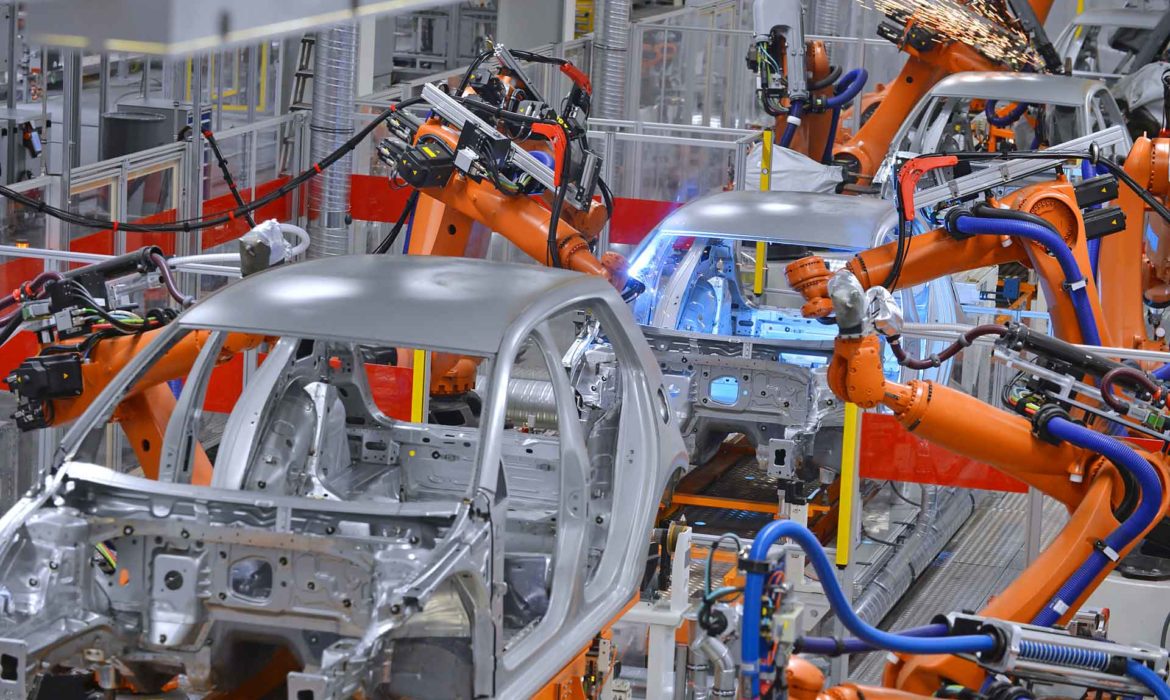

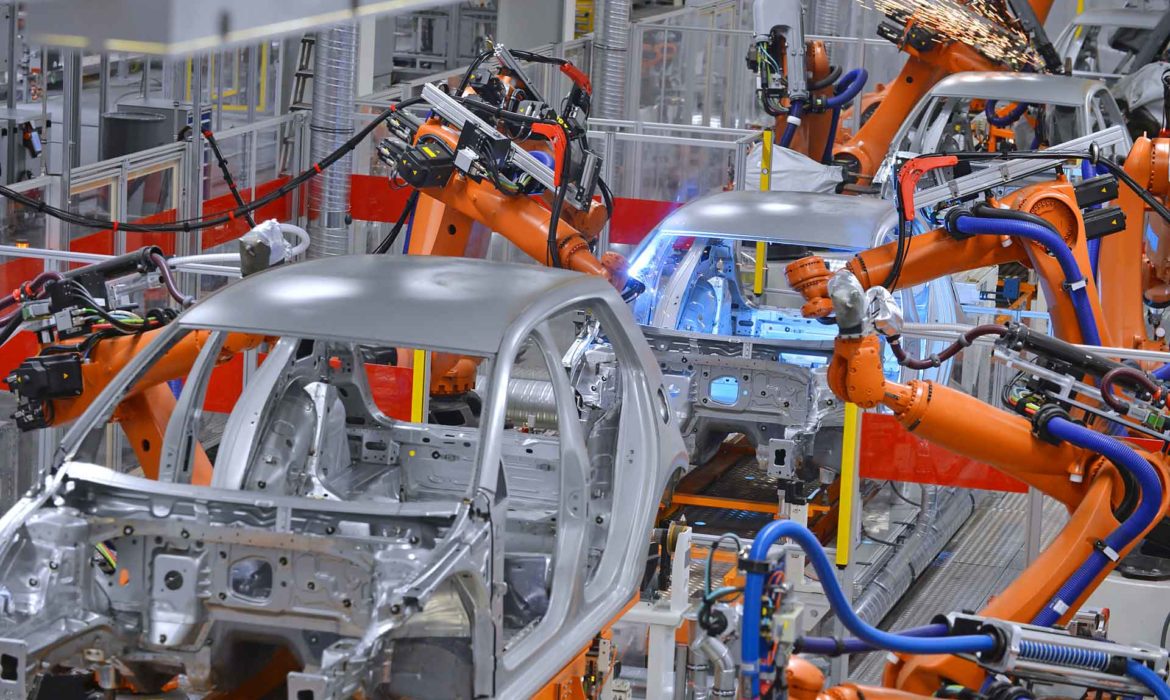

EVs – cost optimisation is key to balancing brand and price

There is now no doubt that the era of the Electric Vehicle (EV) is upon us. This is disruption on a gigantic, global scale and all the hopefuls in this mix are positioning to take commercial advantage of this seismic shift.

Will 2021 be the year supply problems hit car manufacturing?

A shortage of semiconductors resulting from the Covid-19 pandemic could be a watershed moment for automotive OEMs who are willing to adapt to the situation.

Is car ownership back in the driving seat?

Some analysts believe the car ownership model could soon be back in the ascendancy due to COVID-19. What impact is this having on the automotive industry and are there any supply chain implications?

Can automotive aftersales ‘come back stronger’?

Many dealerships and independent service centres were finding it hard to make a profit long before the COVID-19 pandemic hit. Now, as the post-lockdown pipeline starts to refill, there is still time to do things differently.

Disruption – Responding to Change to Maximise Performance

The Covid-19 pandemic has had a cataclysmic effect across all sectors, forcing manufacturers to react quickly to continue to meet market demand. In the first of a series of thought leadership, Vendigital’s new Partners and Director share their views on...

It’s time to pivot in favour of EVs

As automotive supply chains start up again, OEMs have important choices to make about how they rebuild their operations. Has the time come to ‘bet the house’ and invest in the battery electric future?

COVID-19: Supply chain focus is key to automotive industry recovery

Vehicle manufacturers and Tier 1 and 2 component manufacturers should avoid severing relationships with businesses further down their supply chains and look for ways to support them on the way to recovery. Doing so could give them a competitive advantage as the pandemic starts to subside.