5 alternatives to li-ion batteries – pros and cons

In this infographic we look over some popular alternatives to Li-ion batteries that are currently being explored, brake down the pro’s and con’s of each.

Combining our deep operational and industry expertise, and in-house data science capability, our insights provide fresh perspectives and practical guidance to help businesses address the complex operational challenges and issues they face.

In this infographic we look over some popular alternatives to Li-ion batteries that are currently being explored, brake down the pro’s and con’s of each.

New electric vehicle platforms are springing up across the UK, some led by established players, others the work of entrants to the market. Can the newcomers compete?

With so much venture capital up for grabs, electric vehicle (EV) start-ups and other tech companies in the sector have arguably never faced a better opportunity to fast-forward their strategic growth plans.

Here we provide practical guidance on the regulations around shipping lithium ion batteries, including mode of transport, battery capacity and packing method.

UK car makers will have to address some crucial challenges around battery production if they’re going to survive in an age of electric vehicles.

To plot their path to net-zero, businesses will need to instigate a bespoke decarbonisation roadmap and demonstrate their willingness to adapt their operations and systems.

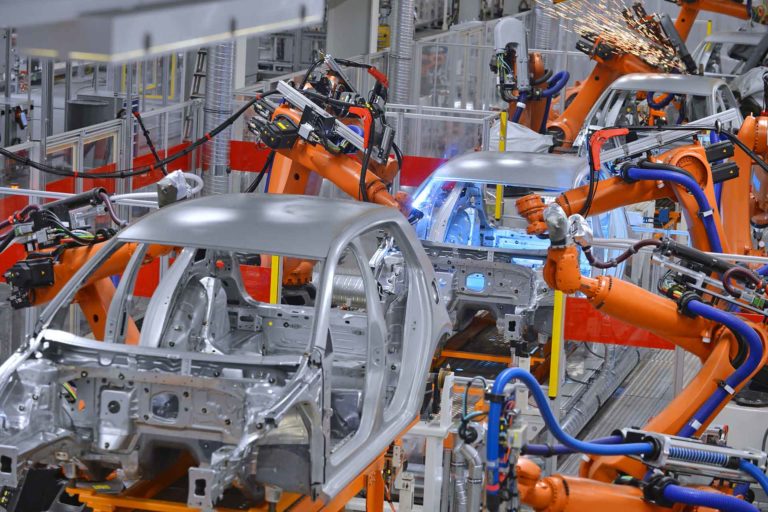

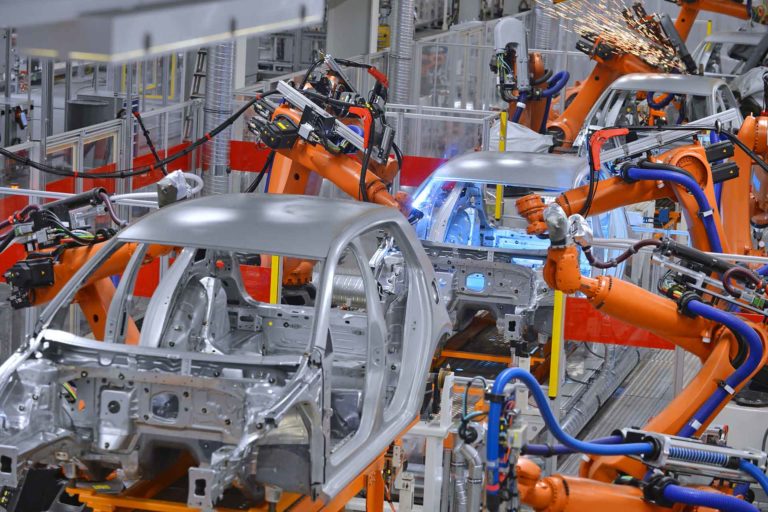

The whole automotive industry is engaged in a pivot towards Battery Electric Vehicles. Supply chain design is a crucial element in achieving the required pivot.

Justin Benson considers the importance of balancing brand and price as established car makers line up to launch new mass market EVs.

Inspirational examples of innovation in response to shifts in market demand have been a stand-out feature of the past year, with many manufacturers pivoting to focus on revenue generation during the pandemic

There is now no doubt that the era of the Electric Vehicle (EV) is upon us. This is disruption on a gigantic, global scale and all the hopefuls in this mix are positioning to take commercial advantage of this seismic shift.

A shortage of semiconductors resulting from the Covid-19 pandemic could be a watershed moment for automotive OEMs who are willing to adapt to the situation.

Some analysts believe the car ownership model could soon be back in the ascendancy due to COVID-19. What impact is this having on the automotive industry and are there any supply chain implications?

Many dealerships and independent service centres were finding it hard to make a profit long before the COVID-19 pandemic hit. Now, as the post-lockdown pipeline starts to refill, there is still time to do things differently.

The Covid-19 pandemic has had a cataclysmic effect across all sectors, forcing manufacturers to react quickly to continue to meet market demand. In the first of a series

As automotive supply chains start up again, OEMs have important choices to make about how they rebuild their operations. Has the time come to ‘bet the house’ and invest in the battery electric future?

Vehicle manufacturers and Tier 1 and 2 component manufacturers should avoid severing relationships with businesses further down their supply chains and look for ways to support them on the way to recovery. Doing so could give them a competitive advantage as the pandemic starts to subside.

Re-making, re-engineering, and transformation are all terms the auto retail sector was discussing before the crisis. The corona virus is offering a real opportunity to turn this rhetoric into reality. If there was ever a moment “not to waste a crisis”, it is now.

With the COVID-19 coronavirus pandemic impacting global supply chains, concerns are growing that some automotive OEMs could be forced to switch components or find alternative sources of supply.

Coronovirus and its sudden impact on the Chinese economy might be occupying the news headlines, but there are broader changes afoot over the longer term.

Accessing and organising data, which is both reliable and capable of delivering valuable business insights, is a constant challenge for high-value manufacturers.

Having recently secured a major £120m bonds deal, Aston Martin appears to be banking on innovating its way through the current tough trading conditions and CEO, Andy Palmer, has promised that its ambitious investment plan can succeed.

The UK’s thriving autotech sector could be making more of Chinese money and investors’ willingness to look further afield for opportunities to fund early-stage R&D activity, says Richard Gane.

Jaguar Land Rover (JLR) has called for the creation of multiple ‘gigafactories’ to provide the large volume of batteries needed to fuel its electrification strategy.

Tech-led innovators are increasingly challenging AMs in the global automotive industry. To keep ahead of the competition, AMs need to accelerate their investment in emerging technologies now.

The failing fortunes the UK car manufacturing industry was dealt yet another blow on Thursday, when Ford confirmed its engine plant in Bridgend will close in September 2020.

Our Richard Gane comments on how procurement and purchasing professionals can drive significant cost savings.

Our Automotive Director, Richard Gane discusses why road users need more information at The Huffington Post.

As Brexit draws nearer, Richard Gane explains why Britain should be developing its own mid-tier manufacturing supply chain, at The Times Raconteur.

Stay connected

Stay up to date with Vendigital by signing up to our email newsletter.